As good as expected

The special heating technology at Richter + Frenzel in Kassel has model character

The special heating technology at Richter + Frenzel in Kassel has model character

The company's credo: "The future lies in innovative, modern technologies. We have to deal with them competently and pass on our knowledge to our clients - craftsmen, planners, architects. Of course, we can argue particularly convincingly if we have our own experience, for example with regard to the energy savings of old versus new." Markus Ortlauf, who says this, is a technical advisor to the wholesale company Richter + Frenzel. A year and a half ago, he had advocated an unusual heating installation in the wholesaler's Kassel property. The operating results after a good year have rewarded him and his company for the not entirely risk-free decision.

Fig. 1: The distribution piped on site with the rendeMIX mixers (to the left of R + F employee Stefan Dornemann and a parallel model installation for training purposes with Magra distributor in the background.

At the centre of the renewed technology is the "Ecocraft" modular boiler from Vaillant. In the northern Hesse branch of R + F, the older atmospheric boilers with acceptable utilisation rates had begun to struggle and were to be replaced. However, it could not be standard goods, because in Hesse, the motherland of Viessmann and Buderus, you have to hold a few trump cards in your hand if you want to survive as a supplier of heat generators, among other things, alongside the two powerful competitors.

Fig. 2: Ecocraft heating system in the technical/training room at R + F in Kassel.

Markus Ortlauf saw and still sees one of the trump cards in the "Ecocraft" gas condensing cascade boiler. Cascade means: The unit consists of self-sufficient modules flanged together in parallel, each module with an output of up to 40 kW. The smallest unit consists of two cells, the largest of seven. This provides an output of up to 280 kW, depending on the object. Each individual burner can also be controlled between 12 and 40 kW, which means that the control range is from 12 to 280 kW.

Disturbance without noticeable consequences

Self-sufficient means: If one of the blocks in the cascade malfunctions, its neighbours work for it. The boiler does not fail. The failure is not noticeable to the outside. The "Ecocraft" is thus similar to a solid diesel, which can also cope with the failure of a cylinder. Ortlauf: "This special feature of this model gives us the chance to play a stronger role with Vaillant in the boiler business. Of course, we also have to communicate this. That's why we immediately expanded the technical room with the "Ecocraft" into a training centre."

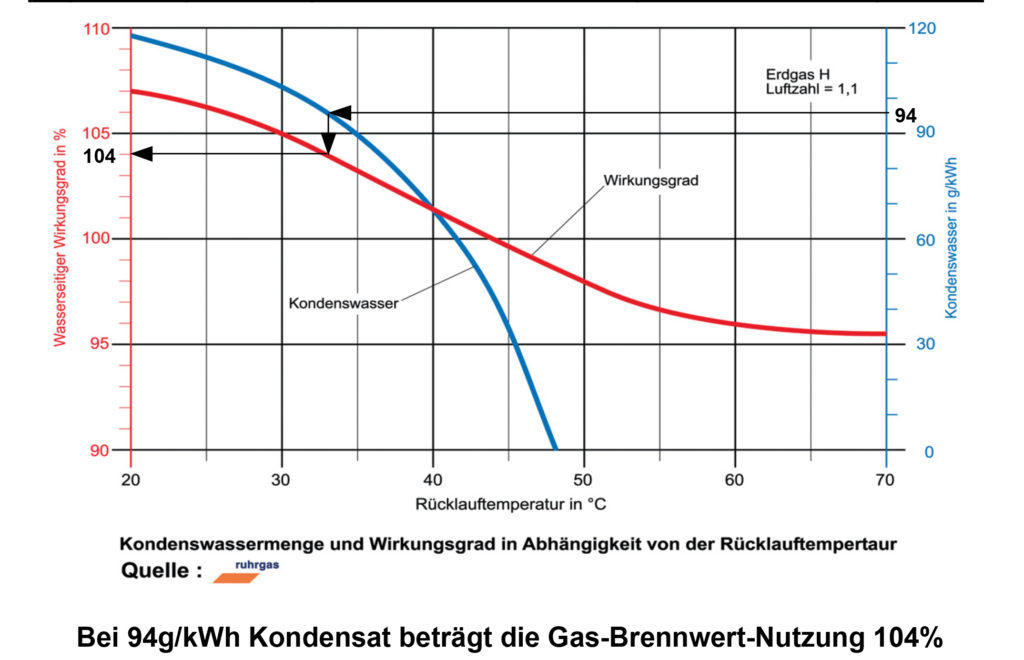

Fig. 3: Condensation heat gain and thermal efficiency in Kassel. See text for explanations.

As a second trump card, which speaks above all for the planning and consulting competence of the Richter + Frenzel field service, the Kassel branch points to the special switching of the three heating circuits of the building complex in combination with the "rendeMIX" system from the company HG Baunach from Hückelhoven on the German-Belgian border. This switches high-temperature and low-temperature networks one after the other, making the return of one heat distribution system the flow of the other, thus optimising the energy yield, especially in combination with condensing boilers. About seven years ago, this architecture based on a very special multi-way mixer came onto the market as a heart. In the meantime, it has passed its test in numerous references, i.e. it has proven its savings effects: because it guarantees the lowest return temperatures and thus the highest condensation heat gains.

Three circles as one circle

In Kassel, the "rendeMIX" found a particularly exciting terrain, namely three temperature zones: firstly, the administration complex as a radiator circuit with a flow temperature of about 60 °C, secondly, the exhibition with underfloor heating for a maximum of 40 °C and thirdly, finally, the warehouse with coils in the floor for a flow temperature of up to 30 °C as well. In principle, this third section is only to be kept frost-free. The system scheme is therefore based on the following spreads: Offices 62/42 °C, Exhibition 40/30 °C, Warehouse 39/20 °C. With "rendeMIX", practically the entire complex is heated as a single-circuit design. In the past of the two atmospheric old boilers, three mixers mixed three temperatures for each subarea, and the common return therefore never fell below 42 °C.

In Kassel, the "rendeMIX" found a particularly exciting terrain, namely three temperature zones: firstly, the administration complex as a radiator circuit with a flow temperature of about 60 °C, secondly, the exhibition with underfloor heating for a maximum of 40 °C and thirdly, finally, the warehouse with coils in the floor for a flow temperature of up to 30 °C as well. In principle, this third section is only to be kept frost-free. The system scheme is therefore based on the following spreads: Offices 62/42 °C, Exhibition 40/30 °C, Warehouse 39/20 °C. With "rendeMIX", practically the entire complex is heated as a single-circuit design. In the past of the two atmospheric old boilers, three mixers mixed three temperatures for each subarea, and the common return therefore never fell below 42 °C.

So, that's about the system. It went into operation at the beginning of the 2005/2006 heating season, and a few weeks later in spring the training courses for craftsmen and planning offices on "Ecocraft" and "rendeMIX" started. The first training courses had to make do with selective results in addition to function. How temperature-stable and with which degrees of utilisation the individual volume flows moved through the pipe coils, through the radiators and through the heat exchangers of the "Ecocraft" could only be read from momentary thermometer readings and from the balance of a few weeks, but not from the balance of two heating periods as a before-and-after comparison.

Such an assessment is now available. In the two years before "Ecocraft" and "rendeMIX", in the years July 2003 to June 2004 and in the same period 2004 to 2005, the heating energy consumption at Richter + Frenzel in Kassel was 506,000 and 499,000 kWh respectively. In time for the winter of 2005/2006, the local heating contractor, Günter Tromp Haustechnik, Kassel, installed the modular Vaillant heat generator and connected the three heating circuits in series with the Baunach fitting. The result: only 356,000 kWh. This value is not weather-adjusted, but read from the gas meter. However, this does little to change the proportionality, as the climate data did not differ greatly in these three years under consideration.

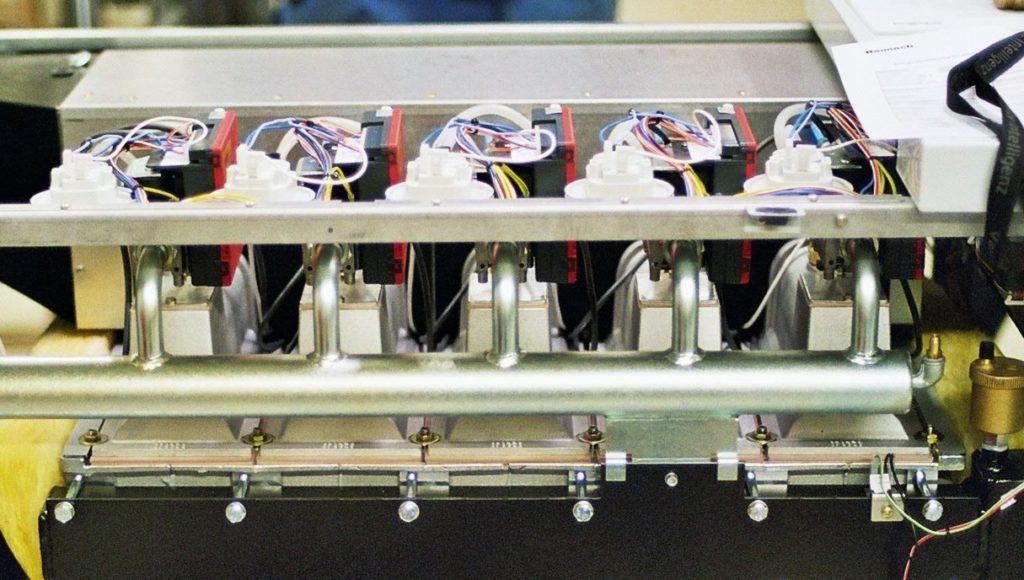

Ecocraft structure

The gas condensing boiler consists of two to a maximum of seven modules of 40 kW each. In Kassel, five blocks with a total of 200 kW are sufficient. Each module is about 14 cm wide, equipped with a fan-assisted overhead burner and controllable between 12 and 40 kW. The individual elements of the cascade work autonomously. In the event of a malfunction, the unit automatically distributes the power to the other cells. In normal operation, the control system switches on as many modules as possible with reduced heat output. The schematic illustrates the operating mode: At 12 kW, only module 1 is running. For 48 kW, for example, two modules with 24 kW each are sufficient. In fact, however, cells 1, 3, 5 and 7 cover this case with 12 kW each. This reduces the load on the combustion chamber and the flue gas temperatures drop in favour of a high system efficiency.

In the picture below, the gas line. Each element consists of a modulating surface burner for the output range 12 to 40 kW, a fan, a gas fitting and the compact high-performance heat exchanger in V-shaped technology made of die-cast aluminium. This material keeps the weight within limits, so that the system is also particularly recommended for modernisation cases, especially in hotels, mixed-use residential/commercial properties, old people's homes, hospitals and similar properties that have to attach importance to high operational reliability.

Fig. 4: Gas line with autonomous burner/blower unit in each case.

Fig. 5: Example of load sharing.

One advantage of the wide modulation range is not only the exact output adjustment in combination with low return temperatures for the benefit of efficient condensing boiler utilisation. It also allows relatively small storage tanks, which would normally not harmonise with a large boiler output, to be loaded for DHW supply. The control of the "Ecocraft" allows parallel operation of the heating and storage tank charging pump. The programme also takes regular thermal disinfection into account.

The kettle is not only restrained in terms of space and weight. It is also hardly noticeable acoustically. Even at maximum load, the 200 kW unit emits no more than a whisper. And of course the cascade can also be conveniently monitored, adjusted or parameterised remotely, for example with a telephone remote control or remote control or with Vaillant's vrnetDialog technology.

Proven to save 30 per cent

Fig. 6: Condensate measuring device BrennCon www.consoft.de.

The modern boiler and the heating circuit arrangement thus reduced the natural gas costs by around 30 percent. Roughly speaking, two thirds of this success can be attributed to the heat generator and the third third to the system design. To realise this, HG Baunach had to do some convincing with the planner and Vaillant. If you look at the three individual spreads and add in some tolerances, the total spread adds up to 40 K. Vaillant initially did not want to impose this difference between flow and return on the heat generator, for fear that a single module might suffer from a lack of water under unfavourable conditions. The Remscheid-based company originally insisted on an overflow, on a hydraulic short circuit. This is because the Ecocraft belongs to the family of recirculating water heaters, and they need minimum volume flows.

The technicians solved this problem from the system side. They built a control hierarchy that is balanced in such a way that individual circuits always guarantee the minimum circulating water quantity when the modules are in operation, i.e. they do not completely regulate down.

The three temperature levels at Richter + Frenzel make do with a total of 200 kW. The training/technology room therefore has an Ecocraft with five modules (5 x 40 kW). The operators counted the starting frequency and determined an average boiler running time of 2.5 days per start. Now this should not be a particularly surprising value for a modulating heating system that can run down to a few kilowatts. In a severe winter, heat demand and heat output would have to balance each other out and the system would virtually run through, but viewed over an entire heating period, 2.5 days speaks for a very solid system configuration.

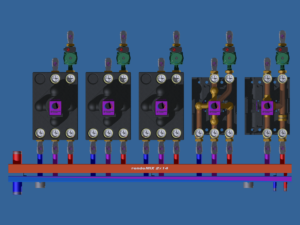

Now Magra distributor for rendeMIX

Fig. 7: rendeMIX with Magra distributor.

If you take a look at the installation at Richter + Frenzel, you will notice that the piping of the individual mixer groups is still very complex. That was expensive. In the case of Richter + Frenzel, this did not play a significant role in the decision because, firstly, they wanted to set up a demonstration plant and, secondly, they were already negotiating with the fittings manufacturer Magra to cast a special distributor for the "rendeMIX". This would later reduce the costs in the commercial business and thus make the special architecture of the series connection more attractive in terms of costs and installation.

Magra and Baunach presented the fitting at the Essen SHK in 2006. It combines the "rendeMIX" scheme with the principle of the familiar manifold. What is special about it, however, is that three connections are provided per mixer group and not two, as in the standard version, namely hot flow, hot return, cold return. The manifold allows up to five groups to be connected. To avoid confusion, the individual couplings are clearly marked. The only thing that needs to be taken into account is the order in which the heating circuits are connected to the heat generator with decreasing return temperature. Otherwise, there is no difference to the proven Magra system.

High calorific value utilisation

This is also expressed in the utilisation of the calorific value. Manufacturers promise utilisation rates of 105 percent as a rule. But there is often a considerable gap between theory and practice or between the test bench and the field. This has something to do with return temperatures that are too high. At a value of about 40 °C, the amount of condensed water is two-thirds that of the "gain" at 20 °C. The result is a loss of five percent. In the end, this amounts to a lost five percent efficiency compared to what is feasible. In the Richter + Frenzel branch, due to the triple use of the flow down to 20 °C, there should actually be no differences between the planned and measured condensation heat yield.

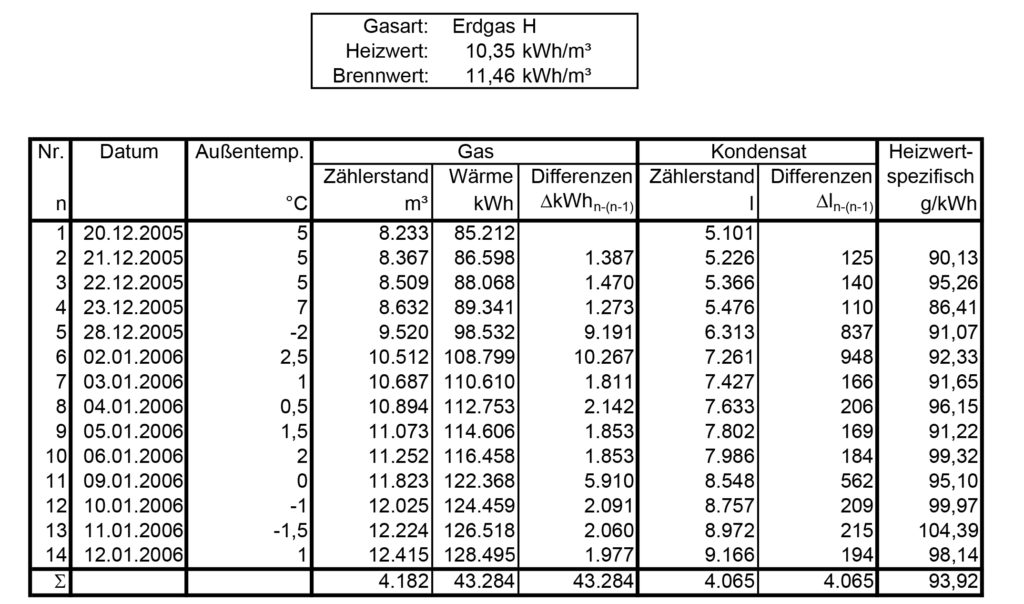

However, the advisors and training managers wanted to base this on verifiable evidence and suggested the installation of a BrennCon measuring device. This purges out the condensation water. In principle, it is a condensate collector with an integrated lifting pump that empties the full container into the wastewater network and determines the condensate volume from the number of strokes. The recalculation by Richter + Frenzel revealed highly satisfactory results: the gas consumption of 4182 m3 or 43 284 kilowatt hours in the period 20.12.2005 to 12.01.2006 are compared with a specific 94 g/kWh of condensate. From this, Fig. 3 reads an average return temperature of about 25 oC and a thermal efficiency of the boiler in the period under consideration of 104 percent. At 42 oC return - as in the past - the "Ecocraft" would have had to settle for around 4 % less effectiveness - and thus give away 16 000 kWh.

Some improvements

At least 16,000 kilowatt hours wasted. In the first weeks of commissioning, the system was still based on older control software that was not tailored to the three-circuit architecture. Vaillant made improvements. Figure 3 also attests to the success: from January, the condensation levelled off at about 98 g/kWh, which means at least another half a percentage point more or 2000 kWh.

Another initial shortcoming: an installation error had crept in. This was probably to the detriment of the system's coefficient of performance as defined by the Energy Saving Ordinance. Unfortunately, as it turned out later, one of the outdoor sensors was permanently reporting frost temperatures. As a result, even in mild weather, the supply flowed into the radiators at the boiler temperature, which was limited to a maximum of 67 °C. The system still had one return flow. Although the return flow temperature remained at 22-25 °C, according to DIN 4701 Part 10 "Energetic evaluation of heating and ventilation systems", the heat loss of the heat distribution system increases as the system temperature rises. However, since the majority of the distribution level in Kassel is located within the thermal envelope of the building, the losses are likely to have been only minimally noticeable in euros and cents.

Bernd Genath