Exhaust gas condenser, return flow boost and buffer efficiency

Flue gas condensers continue the eco-trend towards condensing boiler technology

The idea of extracting additional heat from the combustion exhaust gas by condensing the water vapour it contains has now become widely accepted under the term condensing technology for natural gas and fuel oil boilers. In this respect, it can be assumed that the trend towards condensing technology will also continue for wood boilers and CHP units, especially since there are further advantages to be recorded for each of these technologies:

The idea of extracting additional heat from the combustion exhaust gas by condensing the water vapour it contains has now become widely accepted under the term condensing technology for natural gas and fuel oil boilers. In this respect, it can be assumed that the trend towards condensing technology will also continue for wood boilers and CHP units, especially since there are further advantages to be recorded for each of these technologies:

- With wood boilers, the use of flue gas condensers leads to a significant reduction in particulate emissions of up to 50%. (Source: ÖkoFEN)

- With CHP units, the part of the exhaust gas that is converted into electricity also increases the calorific value balance, so that the percentage increase in heating output is higher than with boilers.

- The use of flue gas condensers is a prerequisite for the joint use of air flue systems (LAS) with other heat generators.

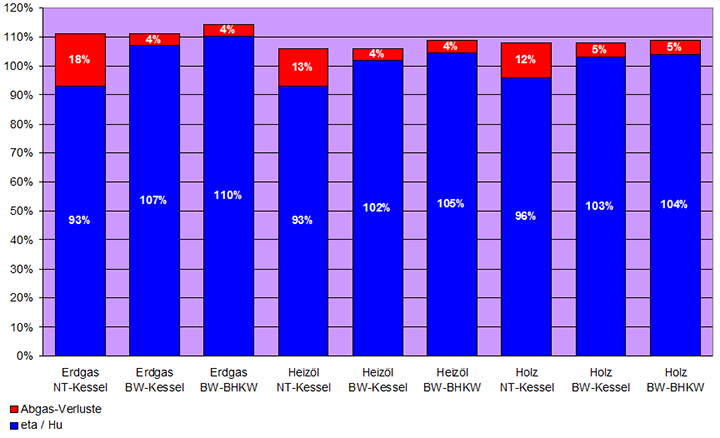

The following table shows the different fuels and heat generator efficiencies:

| Natural gas NT- Boiler |

Natural gas BW- Boiler |

Natural gas BW- CHP |

Heating oil NT- Boiler |

Heating oil BW- Boiler |

Heating oil BW- CHP |

Wood NT- Boiler |

Wood BW- Boiler |

Wood BW- CHP |

|

| eta el | – | – | 30% | – | – | 45% | – | – | 10% |

| Ho / Hu | 111% | 111% | 114% | 106% | 106% | 109% | 108% | 108% | 109% |

| Exhaust gas losses | 18% | 4% | 4% | 13% | 4% | 4% | 12% | 5% | 5% |

| eta / Hu | 93% | 107% | 110% | 93% | 102% | 105% | 96% | 103% | 104% |

Sources: iwo.de, vollbrennwerttechnik.de, ÖkoFEN

At first glance, for example, the heating oil CHP with an efficiency of just below that of a natural gas condensing boiler is surprising, as is the fact that a wood condensing boiler beats a heating oil condensing boiler by one percentage point in efficiency.

From our point of view, there is much to be said for the further growth of this technology. So be there from the beginning and gain experience where others are still closing their eyes!

Condensing boiler utilisation still means undershooting the dew point

However, the art of utilising the condensing value is still called falling below the dew point, because only then does the water vapour contained in the flue gas condense, and there is no way around this physical fact. On the one hand, this means that your heat distribution must be operated with the lowest possible return temperatures. On the other hand, it also means that, for reasons of buffer efficiency, you must be very careful with the limited supply of cold water when loading, because its exhaustion ends the loading of the buffer. The cold water supply of a buffer is as precious during loading as its hot water supply is during unloading!

Condensing value utilisation versus buffer efficiency

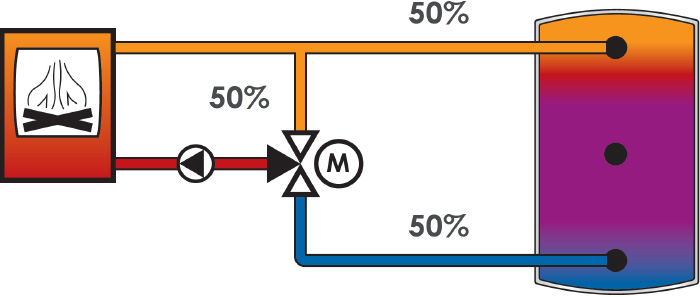

Regenerative heat generators, such as wood boilers or CHP units, usually require a regulated minimum return temperature. This is often around 60°C and is generated by mixing flow water into the cold return from the lower buffer connection.

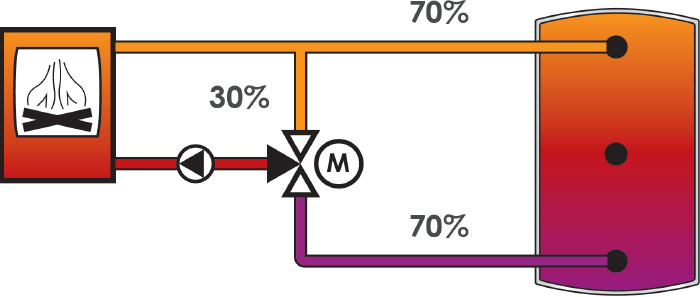

Due to the single-zone loading, a lot of boiler flow water enters the boiler return and only a little enters the buffer.

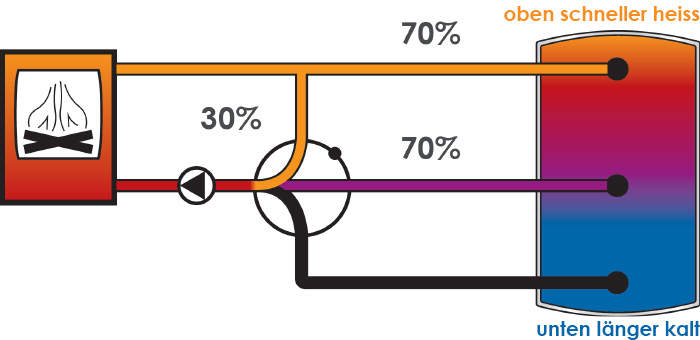

This so-called return flow augmentation (RLA) can be used with a rendeMIX 2×3 for particularly efficient two-zone charging of a buffer tank. With two-zone charging, the upper part of the buffer is first heated as quickly as possible by taking hot water from the middle connection of the buffer.

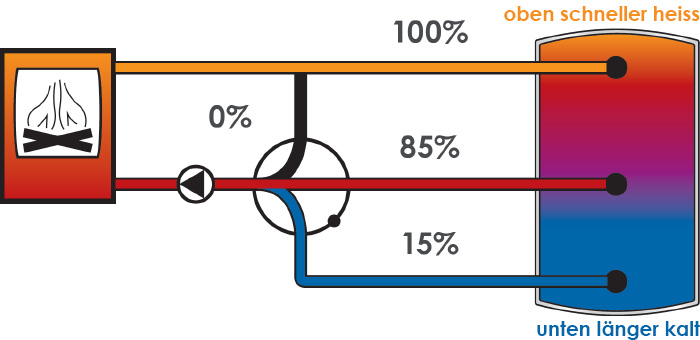

Due to the two-zone loading of the rendeMIX 2×3, less boiler flow water enters the boiler return and more enters the buffer.

Although the temperature at the lower buffer connection also increases with increasing loading of the buffer and thus the proportion of the boiler flow water that enters the buffer, the increase in temperature at the lower buffer connection usually indicates the imminent end of the buffer's heat absorption capacity, because loading must be terminated when the temperature at the lower buffer connection exceeds the required return temperature to the boiler.

Only shortly before the end of single-zone loading do rising temperatures at the lower buffer connection lead to a higher loading rate.

As soon as the buffer water temperature at the middle connection is above the required return temperature, the two-zone loading of the rendeMIX 2×3 accesses the cold water at the lower connection.

The two-zone loading of the rendeMIX 2×3 ensures much more convenient and efficient loading of the buffer thanks to its more economical use of the scarce resource "cold water".

With the same power input, the buffer gets hotter faster at the top and stays cold longer at the bottom. Thus, more comfort (faster hot water) is not a contradiction to more efficiency (longer cold water).

Comparisons between the two systems have shown that the time between firing up a wood boiler and the availability of hot water can be halved while the heat absorption capacity of the buffer is doubled!

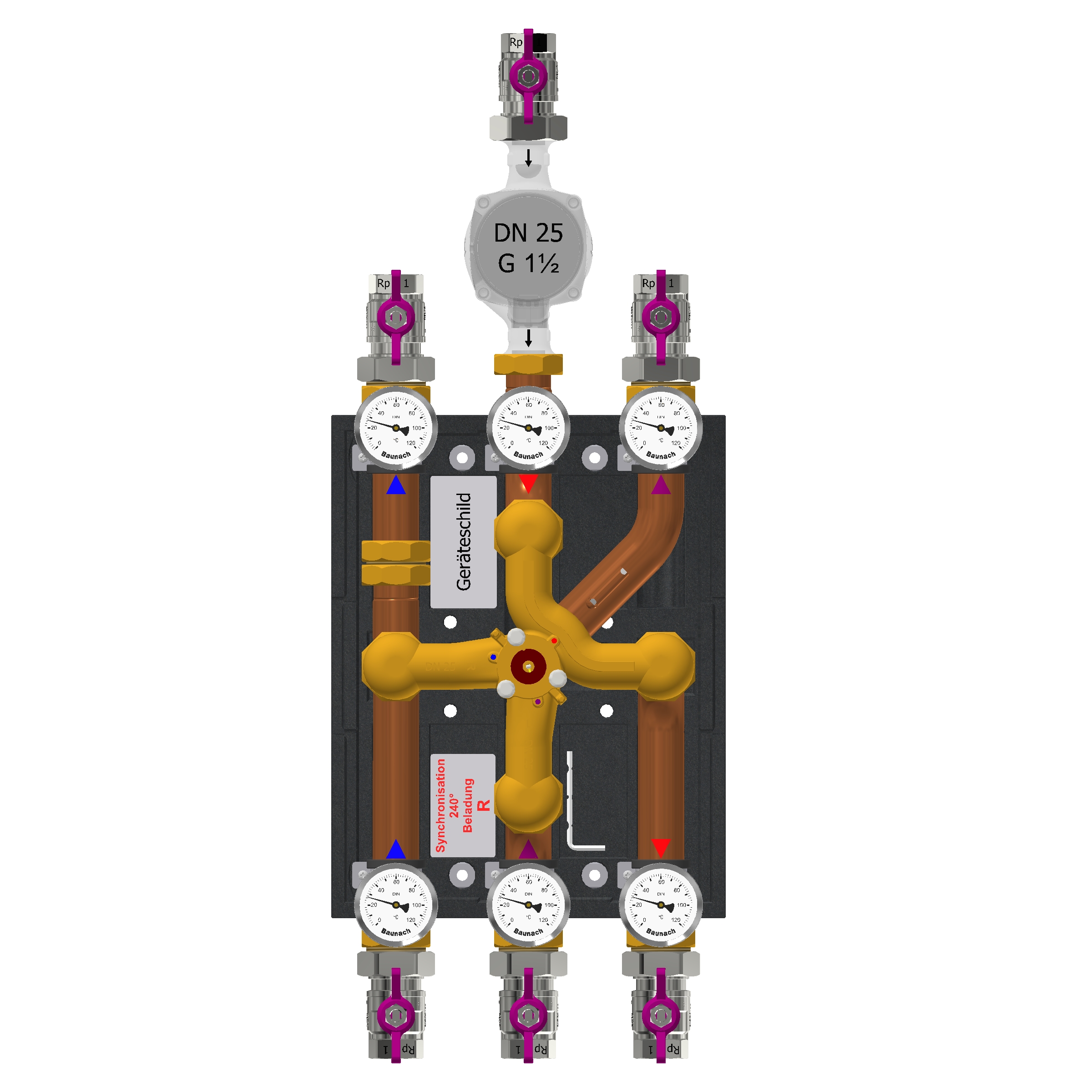

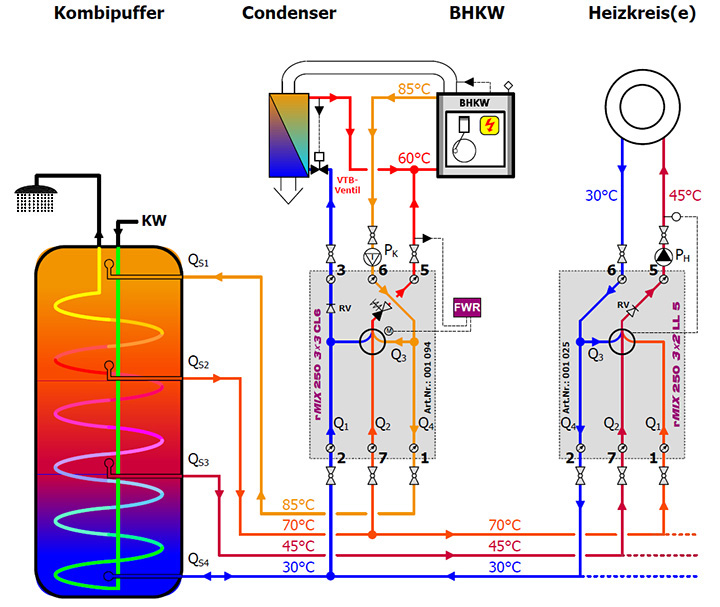

How does the rendeMIX 3×3 Condenser work and why does it need the VTB valve?

The two-zone loading of the rendeMIX 2×3 with integrated return flow augmentation (RLA) loads the buffer tank so efficiently because it heats the warm water from the middle before the cold water from the lower part of the buffer. However, if a flue gas condensing heat exchanger is also to be operated on the wood boiler or CHP unit, this must of course be supplied with the coldest water from the lowest buffer connection in order to achieve the greatest benefit - in other words: to fall below the dew point as much as possible.

The thermostatic flow temperature limiter (VTB valve) with adjustable minimum temperature is responsible for ensuring that no more cold water is drawn from the buffer than is required to achieve the full calorific value effect. It therefore optimises system efficiency by drawing as much cold water from the buffer as necessary, but only as little as possible. To do this, it monitors the temperature of the heating water leaving the condenser and controls the amount of water accordingly: if too much cold water flows through the condenser, the heating water leaves the condenser well below the dew point temperature of the flue gas (natural gas ~56°C, wood: ~49°C, heating oil ~47°C) - the amount of water is reduced; however, if too little cold water flows through the condenser, it leaves well above the dew point temperature - the amount of water is increased. Too little water reduces the condensing yield, as the flue gas does not condense on the entire surface of the condenser. Too much water, on the other hand, does not use the scarce resource "cold water" sparingly enough because the condenser hardly produces any more condensing yield.

However, in order to be able to change the amount of water flowing through the flue gas condensing heat exchanger in the way described, the rendeMIX 3×3 Condenser does not require an additional pump: the necessary differential pressure is simply generated by an overflow valve in the output of the assembly to the return of the wood boiler or CHP. Thus, as before, the entire boiler circuit requires only one circulation pump. This can either be flange-mounted to the rendeMIX 3×3 Condenser or integrated into the heat generator. The only prerequisite for its use is that the line between the flow of the condenser and the return of the heat generator is connected to the rendeMIX 3×3 Condenser via an additional connection (red line with T-piece to connection 5 of the rendeMIX 3×3 Condenser).

The servomotor of the rendeMIX 3×3 Condenser is controlled via the three-point signal 230V~ of an external controller, which keeps the return temperature to the heat generator constant. Alternatively, the rendeMIX 3×3 Condenser FWR has an integrated fixed setpoint controller with adjustable setpoint temperature and 230V~ mains connection.

Only with the rendeMIX 3×3 Condenser can you get the best out of your exhaust gas condenser. and out of your buffer storage tank. Since stratification has a very significant influence on the efficiency of the buffer and this cannot be created or stabilised or protected from destruction during loading alone, it is obvious that the best result is achieved by using rendeMIX loading and unloading at the same time, as we already told you in our rendePOST 4 under "Why do you actually need both: two-zone loading and two-zone unloading?".

Other interesting articles: