Much more than a gunmetal fitting

Four-way mixer as decisive system integrator

Four-way mixer as decisive system integrator

It has been on the market for more than a decade, its benefits and economic efficiency are undisputed, but there is still a lack of widespread acceptance. Perhaps this is because the sophisticated control logic and mixing technology in the four-way mixer "rendeMIX" is a unique selling point. And therefore receives little attention in training and literature. The manufacturer has to take care of market penetration himself in courses and seminars. DKZ sat down at the school desk.

"The main problem of conventional charging and discharging of buffer storage tanks, i.e. the usual single-zone charging and discharging, is mixing. This significantly limits the amount of heat that can be effectively used.

Picture 1: Würzburg, summer 2013

It is simply not possible to prevent the inflowing and outflowing water in the container from causing circulation, which reduces the temperature in the hot zone and builds it up in the cold zone, down at the bottom. The advantage of dual-zone charging and discharging with the 'rendeMIX' is that hot, cold and mixed water - mixed water through return use - only flow in and out of their respective zones. A kind of safety shield builds up in the middle of the buffer. This stabilises the separation between the upper hot half and the lower cooler half in the boiler. The stratification is maintained."

Hans-Georg Baunach explains the energetic and hydraulic advantages of the multi-way mixer "rendeMIX". Location: Würzburg in late summer last year. Occasion: Hydraulics seminar of HG Baunach GmbH & Co. KG. Topic: Increasing the efficiency of heating systems. "Efficiency is the result of the harmonious cooperation of several components within a system. The "rendeMIX" principle supports you in setting up efficient heating systems. The seminar reveals the dormant efficiency potentials in your customer systems - and how you can bring them to life."

Versatile use

That is exactly why the 16 master craftsmen had accepted the invitation and come to Würzburg. About 15 years ago, the Company Baunach from Hückelhoven on the left bank of the Rhine attracted attention for the first time with its special control technology.

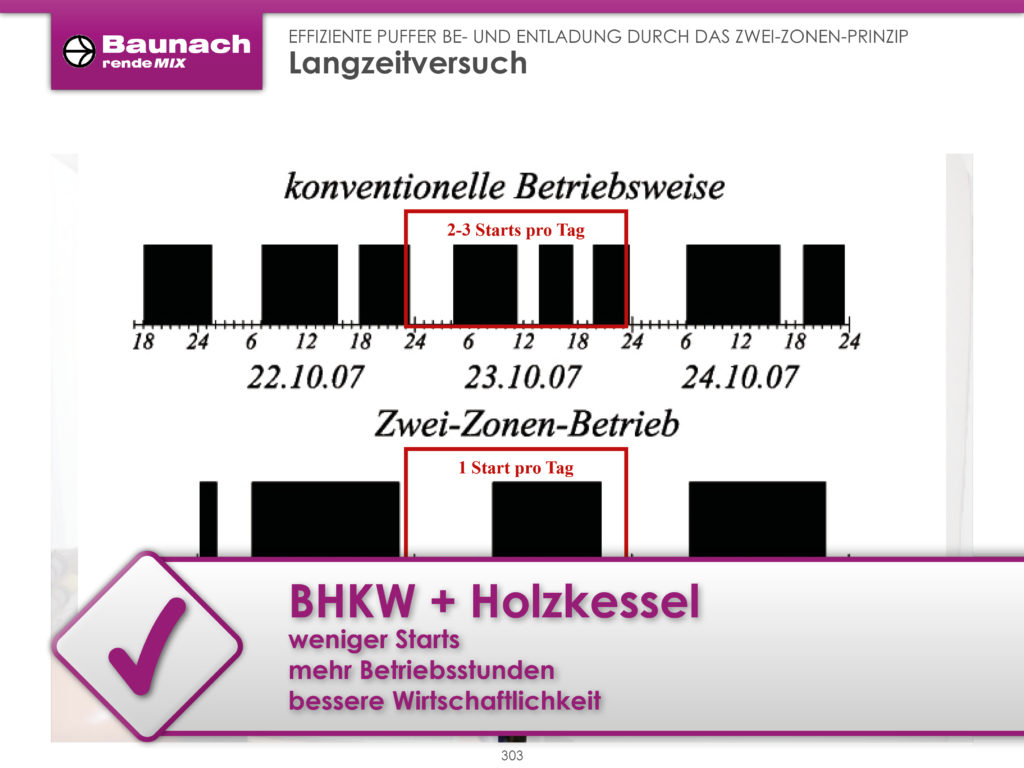

Fig. 2: 240 percent instead of 100 percent heat storage in the 100-l buffer, test result Biberach University

At that time, the focus was on connecting a high-temperature circuit (radiators) in series with a low-temperature circuit (underfloor heating). This scheme is standard in single-family houses in many regions of Germany. The patented method makes the return of the high-temperature circuit the flow of the underfloor heating, although completely different amounts of water circulate. The internal equalising sections in the four-way mixer and the mixing structure - the technology uses different temperature levels to mix the flow temperature precisely to the degree and in an energy-saving manner - solve this switching task, which can hardly be done by hand (Fig. 2).

"For you, however, this does not mean that you have now taken an advanced course in thermodynamics in order to understand the device. It does most of the work by itself. The unit is controlled automatically only via the temperatures. You do not have to adjust any volume flows. You are only supposed to understand the philosophy here at this training course," says the lecturer, allaying the fear of too much theory.

In the meantime, the range of applications has expanded noticeably - noticeably in the sales of the fitting. Innovative installation companies use the component in various systems. Firstly, of course, for coupling a high and a low temperature circuit. Secondly, for loading two-zone buffer storage tanks. In this case, the rendeMIX ensures that the stratification in the storage tank is maintained as long as possible. Thirdly, it loads and unloads the tanks in a similarly clever way to the Baunach development, with the result that the running time (annual hours of use) of solar systems as well as small CHP units is extended economically.

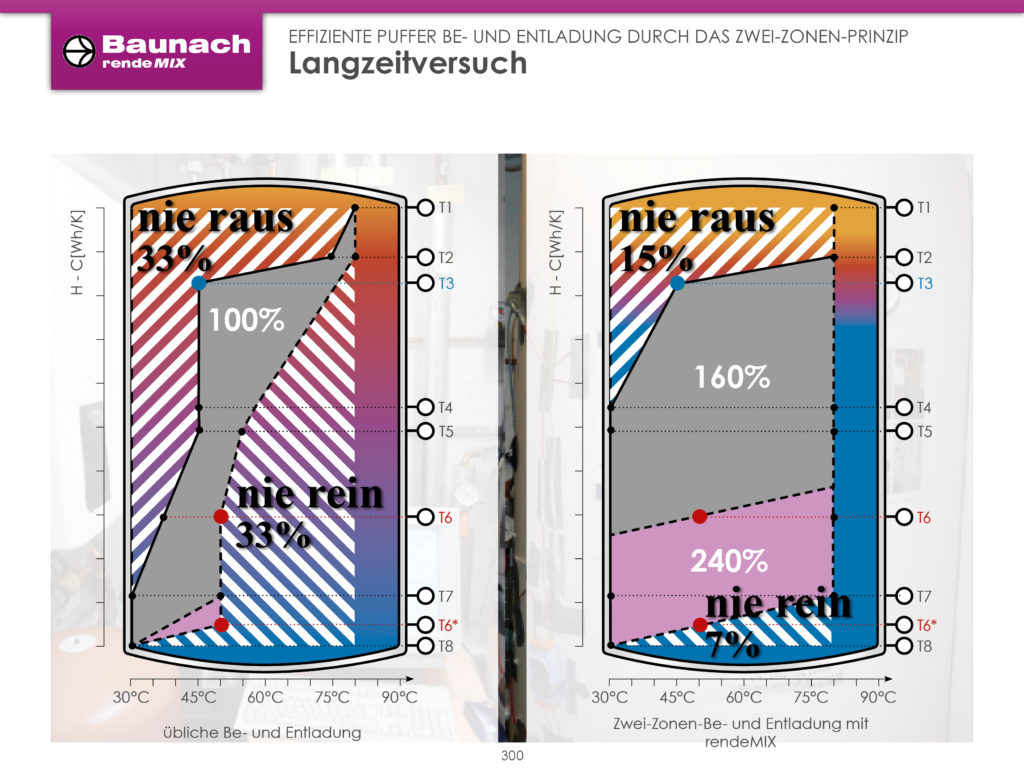

Doubled boiler running time

Fig. 3: Mixing principle in dual-circuit systems

Question to the auditorium: "At what rhythm do you have to top up a log boiler?" "After two days at the latest." "Yes. And that's why your customers can't easily go away for the weekend. The mixer here virtually doubles the convenience of a log boiler. The heat generator does not burn its fill within two days, as it used to, but the 'rendeMIX' uses the storage volume of the buffer so skilfully that the sensors of the primary air control report 'no heat demand yet'. The boiler heats for four days in economy mode. The family can go skiing in the winter at the weekend without having to come back to a cold flat on Sunday evening or having to harness the neighbour. This has been confirmed several times." (Image 3)

The company boss convincingly explains the two-day profit using the flow diagram inside the gunmetal housing.

Figure 4: Condensed water quantity and efficiency of gas condensing boilers as a function of the return temperature (Image: Ruhrgas AG)

His audience listens attentively. Hans-Georg Baunach knows how to present the actually dry and complicated subject of "hydraulics" in a lively, entertaining and understandable way. Gestures and diction make the theory almost visible.

And, of course, the weaknesses of common installation technology: "What matters is not how much heat is contained in the buffer tank, but what benefit it provides. We distinguish between valuable exergy and less valuable anergy.

A mixed storage tank is not only too cold to prepare drinking or bathing water satisfactorily, with the result that the boiler actually has to cycle unnecessarily frequently, it is also too warm at the same time to be able to absorb solar heat, for example - a double damage, in other words." The damage lies in giving away the (solar) heat and capacity on offer.

The crucial physics

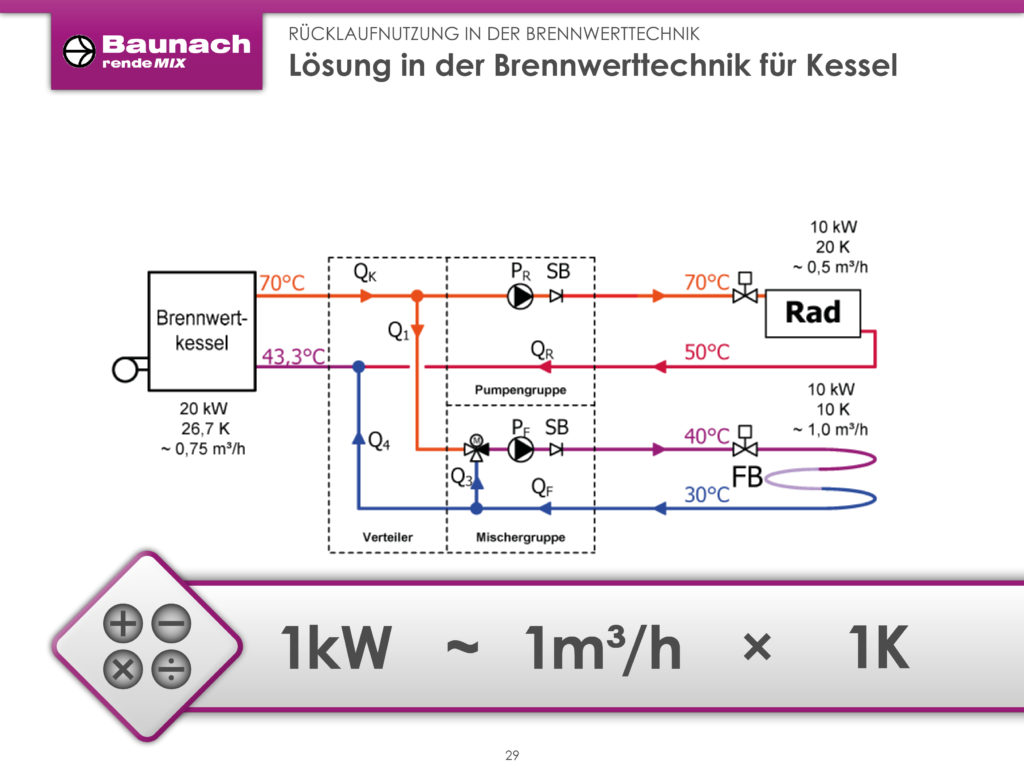

A rule of thumb runs through the five-hour event in variations:

Fig. 5: Return flow utilisation in condensing boiler technology: hydraulic separator and radiator pump saved plus 8 percent higher efficiency (according to Fig. 4)

"Please remember: 1 kWh roughly corresponds to 1 m3 Storage water x 1 Kelvin Delta T". A delta T of 10 Kelvin or degrees Celsius allows a buffer with 1 m3 volume already 10 kWh to be taken out or added. "The greater the delta T, the greater the capacity in one direction or the other. Therefore, the lower the return temperature, the smaller the storage tank may be. In the table you can see how large, depending on the delta T, a buffer must be that is to provide 15 kW for 8 hours." With "rendeMIX", the storage tank may be two numbers smaller in the example.

The fitting strives for a high temperature spread for the purpose of more compact designs or to increase the storage capacity of installed capacity. The Biberach University of Applied Sciences has calculated to what extent the two-zone charging and discharging with return utilisation, which the mixing principle allows, brings in additional yield. A 1,000-litre buffer was put to the test. This served a CHP unit with a flow temperature of 90 °C. With a return temperature from the high-temperature circuit of 50 °C, a theoretical storage capacity of 47 kWh was calculated. In fact, however, only 17 kWh could be withdrawn with the standard connection of the withdrawal fitting (single-zone discharge): In this case, the theoretical capacity is reduced by a factor of 2.7.

Results from Biberach University of Applied Sciences

Fig. 6: Hardly any gain in calorific value at 43 °C return temperature of conventional mixing technology

The blame for this low efficiency - as the Biberach University of Applied Sciences proved - is the inevitable mixing in the buffer storage tank during conventional charging. It significantly reduces the usable amount of heat because it destroys the stratification. In the second part of the experiment, the supervisors changed the charging strategy to the two-zone charging and discharging operating mode with the rendeMIX. The actuators now did not mix hot with cold, but hot with warm and - depending on the setpoint specification - warm with cold water. The loading side was such that the upper buffer zone only received hot water and thus heated up faster, the lower zone consequently remained cold longer. For unloading, the control first took heat from the middle storage connection from the lower buffer zone. This caused the lower zone to cool down more quickly. The upper buffer zone consequently remained at a high temperature level.

Result: The effective storage capacity climbed by around 60 percent from 17 kWh to 27.4 kWh. If the locations of the sensors on the storage unit that switch the CHP on and off were optimised, the usable buffer efficiency could be increased by another 30 to 50 percent in the case of Biberach (Figure 4).

Hans-Georg Baunach condenses the conclusion of the Biberach Report with his words: "The mixing principle is quite simply explained. Imagine you have a bucket of 55-grain water and a bucket of 45-grain water. You can pour them together to make two buckets of 50-grain water. Now take two buckets of 30- and 70°C, you can also mix them to make two buckets of 50°C. Nothing is gained from this side. Only: In the first case, you have a maximum of 55 °C at your disposal, in the second case 70 °C. If you need a flow temperature of 65 °C somewhere in winter, the low delta T or the 45 °C in the storage tank are of little use. The boiler must reheat. At 70 °C you can fall back on the storage tank. That's how the rendeMIX thinks."

The difference to stratified storage

As already expected by the lecturer, at some point the usual question comes up: "So how does a stratified storage tank differ from your method, Mr Baunach?"

Simple answer: "Mine works". The ideal stratified storage, says the developer, is equal in principle. But the emphasis is on ideal, on clean stratification. But that is hardly possible with the flap controls and other tricks. "The 'rendeMIX', on the other hand, takes the warm storage water from the middle of the single-zone discharge between hot at the top and cool at the bottom and mixes it either with the flow or the return. It makes more sense energetically to cool down warm water instead of hot water or to heat up warm water instead of cold (return) water, depending on the situation". Furthermore, this form of discharge from the centre of the buffer stabilises the hot and cold zones.

Functional description

The patented rJET 3×4 with its three connections ensures optimum stratification in the buffer tank during discharge by first feeding the return flow of the radiators into the system separation of the underfloor heating before accessing the hot boiler flow. This means that neither a hydraulic separator nor an additional pump is required upstream of the system separation. The built-in overflow valve keeps the differential pressure above the system separation constant at around 60 mbar. The warmer excess of the radiator return is fed back into the centre of the buffer separately from the cold return of the floor circuit. The buffer stays hot longer at the top and gets cold faster at the bottom, which increases both the solar yield and the hot water comfort. The advantages at a glance:

- Simplest installation due to compact assembly

- Up to 100 percent more solar yield due to cold zone in the buffer tank

- Up to 100 percent more hot water comfort due to hot zone in the buffer tank

- No diverter and no additional pumps required in the heating circuit and upstream of the system separation

The classic, return utilisation, not only benefits the connection of a low-temperature circuit with a high-temperature circuit. Cold returns and smaller volume flows optimise the efficiency of condensing boilers, solar thermal systems, heat pumps, transfer stations and distribution networks. Condensation also produces flushing "wash water": this reduces fouling and corrosion on the flue gas side of the condensing heat exchanger, ergo increasing its life expectancy. This, too, has been proven.

At what point does condensation gain?

Speaking of condensation. Question: "How much condensation occurs at a return temperature of 50 °C, what do you think?" The audience is reluctant to give a millilitre figure. But probably quite a bit, given that the exhaust gas dew point of natural gas is just below 60 °C. "Nothing, zero, only at about 47 °C does it just drip. The theoretical 58 °C dew point temperature does not take into account any excess air, which we regularly use, and you also have to take into account the necessary delta T in the condensing heat exchanger between the exhaust gas and the return.

Via Power Point, diagrams from Ruhrgas AG light up on the screen. The first one shows that the zero point of condensation is at 48 °C return temperature. And also that at 45 °C only a thin 30 grams of water per kilowatt hour sweat out - out of a possible 110 grams with a 20-gram return. With "rendeMIX", the temperature of the heating return should settle at 30 °C or 90 grams of condensate per 1 kWh. "And that increases the efficiency of the boiler by 8 per cent compared to the 50 °C. I didn't calculate that, that's what Ruhrgas says," says Hans-Georg Baunach.

Figure 7: Long-term test. Buffer loading and unloading according to the two-zone principle

The Ruhrgas diagrams

Figure 8: Combination of solar system with gas boiler

The next diagram in the lecture shows the dependence of the dew point on the air number. "Fluctuations in the air supply cannot be ruled out for various reasons. The firing must not soot, so the burner works with excess air, as a reserve, so to speak. This also lowers the dew point, as just shown in the picture, and consequently the calorific value gain. Between the air figures lambda 1 and lambda 2, just to name the basic values, the difference is 10 K, so the dew point drops from 58 °C to 48 °C. And from this you still have to subtract the necessary degrees of spread in the condenser. Use burners with a low air ratio as far as possible, for example premix burners, in order to achieve condensing value utilisation even at somewhat higher return temperatures.

Figure 9: The hardware

Half of the seminar is a revision course. It digs up things that have been lost and makes connections clear again. The explanation of the chick technology in Baunach's four-way mixer takes only a little time; the focus is on the problems of today's heating systems. The economic efficiency of these systems is increasingly being called into question because there is hardly any justifiable relationship between expenditure and efficiency gain. "But it is not the technology or the price of the components that are to blame. The cause of the disproportion is the lack of an overall systemic view. There's no other way to put it: simply adding parts together without thinking about the interrelationships simply erases many percentage points of efficiency gains.

Aim for system unit

The four-way mixing principle makes a noticeable and profitable contribution to improving system efficiency in heat generation (condensing value utilisation), in heat distribution (coupling of high and low temperature circuits) and to system efficiency in heat storage (two-zone charging and discharging with return utilisation). Gas and oil boilers and thermal systems benefit just as much as biomass heat generators, heat pump systems and solar collectors or corresponding combinations. Whether the optimum efficiency is achieved is basically decided on the system side. The circuit diagrams and heat flow diagrams presented in the seminar show why.

Hans-Georg Baunach summarises: "One of the mistakes of the past was to connect cold and warm returns and to return them to the boiler together as one line, thinking that the burner would not have to add so much. Such a circuit unfortunately obstructs the more effective possibility of recovering a lot of residual heat from a warmer medium with the help of a colder medium, possibly even enough to heat a complete section with it. And vice versa: If a flow of 50 degrees is sufficient at midday and the multi-way mixer actually only takes these 50 degrees, 80 degrees are still available in the building in the evening from the upper zone. If, on the other hand, the control system had tapped the 80 degrees and lowered it to 50 degrees with cold water, the boiler would have to reheat in the evening."

www.baunach.net

Bernd Genath