Save fittings, save assembly time

Oil heating with simplified heating hydraulics trimmed for efficiency

Oil heating with simplified heating hydraulics trimmed for efficiency

The standard version of the Baunach hydraulics regulates the return of a radiator circuit to the flow of a low-temperature underfloor heating system with energy efficiency, accurate to the degree and litre. The high-temperature side is the responsibility of the oil or gas boiler, which is operated on a sliding scale. The use of renewable energies, however, is associated with constant boiler water temperatures in most cases - and consequently an additional mixer for the radiators. A heating engineer therefore suggested an extension of the "rendeMIX" scheme. Baunach implemented the suggestion. How? The example of the Backnang heating centre explains it.

There is no better way to put it: "Boiler efficiency alone is not a yardstick for economical heating. Boiler/boiler combinations - even as new condensing boiler systems - are as old as central heating itself in terms of system technology. The responsibility therefore lies in improving the annual efficiency of a system: this means that it is not only necessary to consider individual components, but the entire heating system from the cellar to the living room must be evaluated. High energy efficiency requires perfect system coordination. According to this maxim, taken from a brochure, planning and installation must be carried out. However, for whatever reason, practice does not always adhere to this imperative. It, the implementation, often gives away a lot of the efficiency potential. The renunciation of efficiency points, of course, also has to do with the fact that the knotting into an optimal unit would often have to be done manually: with cost-increasing additional fittings and components. And above all with cost-intensive time: thinking, recording demand, setting correctly and checking - that's expensive, who pays for that?

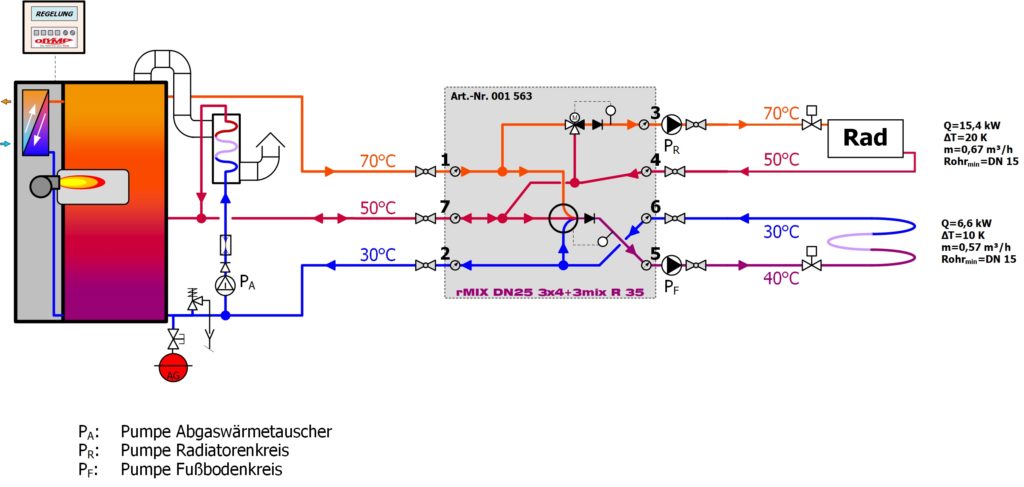

Fig. 1: The circuit diagram of the two-mixer fitting.

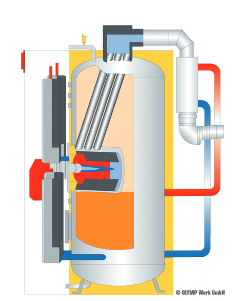

Fig. 2: Section through the Olymp buffer storage "heating centre". The diagonal flue gas flues temper the storage water (boiler water) in the oil condensing boiler. The downstream condensation heat exchanger is hidden in the thickening in the flue gas pipe behind the boiler.

The system idea

That's why some manufacturers are solving the current task of reducing primary energy consumption with well thought-out system offers from the factory - which, of course, requires innovative craftsmen who both recognise the energy advantage and are able to pass it on to the customer in an argumentative way. The eco "heating centre" of the Olympus Work GmbH stands for such an alternative to conventional heating system construction. Incidentally, the opening sentences quoted above come from the flyer for this heat generator. In principle, they already explain the essence of the multi-energy centre: heat source, generation, storage and distribution have the same weight. In the case of the Olymp central unit, generating and storing means that flue gas pipes run diagonally through a buffer storage tank, act as heat exchangers and heat the storage tank contents of 350 l to a maximum temperature of 75 °C.

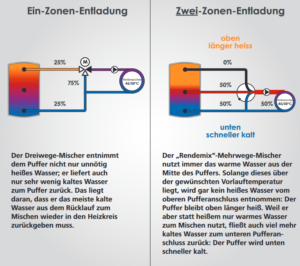

The two-zone heat accumulator allows different temperatures to be stored according to their level and to be withdrawn according to demand. "If warm heating water is sufficient as a flow, one should first take the warm heating water from the middle of each storage tank before mixing valuable hot water with cold water in an autonomously destructive way," says Hans-Georg Baunach, the second in a trio of efficiency apologists who renovated an oil heating system in Backnang, Baden-Württemberg, in an exemplary manner. His company has developed the multi-way mixer "rendeMIX", which independently carries out the temperature-correct two-zone unloading (and loading) on the Olymp boiler.

Two-zone loading and unloading

Originally, the "rendeMIX" only wanted to couple two heating circuits with different temperature levels, namely to connect a low-temperature surface heating downstream of the high-temperature radiators by making the return of the radiators the flow of the underfloor heating. Among other things, this requires an internal bypass to independently compensate for the different flow rates of the radiators on the one hand and the pipe coils in the screed on the other hand on the part of the fitting. Meanwhile, however, the "rendeMIX" can do much more. For example, as just mentioned, it can charge and discharge graduated temperature zones in a storage tank, integrate solar heat and more. The "3×4" mixer type (three connections to the buffer, four to the two heating circuits), which is installed in Backnang and about which details will follow in a moment, decides between the three zones hot (top), warm (middle) and cool (bottom) in one tank. Of course, the buffer must contain appropriate connections. The Olymp heating centre can come up with this.

Originally, the "rendeMIX" only wanted to couple two heating circuits with different temperature levels, namely to connect a low-temperature surface heating downstream of the high-temperature radiators by making the return of the radiators the flow of the underfloor heating. Among other things, this requires an internal bypass to independently compensate for the different flow rates of the radiators on the one hand and the pipe coils in the screed on the other hand on the part of the fitting. Meanwhile, however, the "rendeMIX" can do much more. For example, as just mentioned, it can charge and discharge graduated temperature zones in a storage tank, integrate solar heat and more. The "3×4" mixer type (three connections to the buffer, four to the two heating circuits), which is installed in Backnang and about which details will follow in a moment, decides between the three zones hot (top), warm (middle) and cool (bottom) in one tank. Of course, the buffer must contain appropriate connections. The Olymp heating centre can come up with this.

The third innovative partner in the Backnang project, Fabian Lutz, Managing Director of Malu GmbH from Weissach im Tal near Stuttgart, brings Olymp and Baunach technology together to form a solid unit. "For us, environmentally oriented thinking and acting is a directive; we are guided by respect for nature. This means that we use resources as economically as possible. When we realise that there is still a reserve, we make an effort to use it," the heating engineer explains his proposal to Baunach to "upgrade" a variant of the "rendeMIX" mixer in such a way that it can be exchanged for the existing conventional components in the Olymp-Öko "heating centre" without any installation effort when it comes to connecting a low-temperature circuit to a high-temperature circuit according to the Baunach scheme.

Tripled capacity in the same memory

There is concrete talk of this: an increase in the annual utilisation rate of seven to ten percent, better utilisation of the existing buffer volume through intelligent, temperature-oriented loading and unloading, so that the storage capacity is increased by a factor of two and three, a reduction in burner work to 4,000 starts per 2,000 operating hours, ergo long running times of an average of half an hour in a residential house with 270 m2 of heated space, with radiators on the upper floor and underfloor heating on the ground floor.

Admittedly, neither the Olymp buffer boiler nor the multi-way mixer "rendeMIX" are novelties. What makes the refurbishment of the residential building in Backnang so worth mentioning are the operating data just mentioned as a result of the conversion of the new boiler to the mixer technology from Hückelhoven and its design adaptation to buffer storage boilers for two mixing circuits: The oil condensing boiler with a maximum output of 24 kW contains as standard two quite normal mixer groups with two three-way mixers for the two separately and thus suboptimally fed high and low temperature circuits. Due to the relatively high temperature of the common radiator/area heating return, the condensation yield is also limited in the factory version. The central heating unit is fired by the "rocket burner" from MHG. The relatively large boiler water volume of 350 l makes it possible to install the blue burner from MHG, which is not entirely quiet in principle. Fabian Lutz justifies this decision with the good experience he has had with this type for many years. "Admittedly, the sound level is somewhat higher than that of the competition, but the amount of water dampens the resonance. In any case, the sound emissions have not increased audibly, as the house residents confirmed to us."

External condensing heat exchanger

The blue flame signals a largely loss-free conversion of the chemically bound energy of the heating oil into heat. The burner was developed years ago in cooperation with the German Aerospace Centre (DLR). In the meantime, the trade offers the third generation. In addition to the buffer principle, it should be said that the boiler does not work with an integrated but with a downstream condensing heat exchanger. This is located in the flue gas duct outside the jacket, just before it enters the chimney. A corresponding diverter with pump forces a partial flow exclusively of the cold return from the underfloor heating into and through this heat exchanger, with the result that a high percentage of the water vapour condenses out. The heat released in the process heats up the partial flow and the now hot water volume flows into the corresponding zone of the heating cabinet buffer. The acidic condensate seeps into the sewage system via a neutralisation unit.

The blue flame signals a largely loss-free conversion of the chemically bound energy of the heating oil into heat. The burner was developed years ago in cooperation with the German Aerospace Centre (DLR). In the meantime, the trade offers the third generation. In addition to the buffer principle, it should be said that the boiler does not work with an integrated but with a downstream condensing heat exchanger. This is located in the flue gas duct outside the jacket, just before it enters the chimney. A corresponding diverter with pump forces a partial flow exclusively of the cold return from the underfloor heating into and through this heat exchanger, with the result that a high percentage of the water vapour condenses out. The heat released in the process heats up the partial flow and the now hot water volume flows into the corresponding zone of the heating cabinet buffer. The acidic condensate seeps into the sewage system via a neutralisation unit.

Info

From practice for practice

Heating technology is increasingly encountering this situation in combination with renewable energy sources such as wood, pellets, solar - and in the future also in combination with virtual power plants that want to store away negative electrical control energy in a heating water boiler: high temperature circuit plus low temperature circuit plus constant boiler water temperature. In the article, this already came up with the remark that with these designs, the possibility of directly operating the high-temperature circuit with an outdoor temperature-dependent sliding boiler temperature is omitted. In the past, the heating engineers therefore had to manually install a three-way mixer for the radiators behind the "rendeMIX". This took up space and wasted expensive installation time. Malu GmbH, which is also increasingly confronted with these conditions, was disappointed by this forced installation compromise. She spoke to HG Baunach GmbH & Co. KG in Hückelhoven: Can't a three-way mixer and the "rendeMIX" manifold be accommodated in a single fitting? And is it possible to design the connections of this fitting so flexibly that its spigots fit the flow/return pipework of most heat generators as well as the Olymp "heating centre", so that it only has to be unscrewed and screwed on? Of course it does, replied the Baunach technical department. They recognised this gap in the programme and designed the combination of the "rendeMIX" with a three-way mixer to be presented for the first time at the ISH 2015: The low-temperature circuit in the form of underfloor heating feeds from the three zones hot, warm and cold according to the classic "rendeMIX" scheme, although only two gates are ever open at the inlet. The temperature sensors at the mixer outlet decide from which zones the multi-way mixer draws the water. From this point of view, its respective momentary position with two open inputs and one output does not differ from that of a conventional three-way mixer. Thus, it also reacts to the usual three-point signal of the standard control of almost any boiler. In other words, the "rendeMIX" can handle any controller that drives a normal three-way mixer motor. Of course, this applies all the more to the high-temperature mixer in the new fitting.

With this circuit, it is important that the volume of the partial flow matches the output of the condensing heat exchanger exactly. The adjustment is first done with the help of mathematics by calculating the flow rate from the desired spread between flow and return and the kilowatts of the condenser (2.5 kW). The fine adjustment is then made by measuring the flue gas temperature:

Hot water preparation in summer is considered a critical operation. This is when no cold water is available from the return flow of the underfloor heating. To ensure that a large part of the latent heat of the flue gas is nevertheless used for domestic hot water preparation, the volume flow should be adjusted manually until the flue gas temperature has reached its lowest point, i.e. until it does not drop any further. The pump should be throttled accordingly. This is because if too little cooling water is admitted to the exchanger, the exhaust gas temperature will not drop to the possible minimum. Consequently, the condensation gains would be limited. Although the mass flow would go back into the storage tank at a relatively high temperature, it could well have been a few litres, i.e. a few calories, more.

How to adjust the condensation?

If the cooling water flow to the external heat exchanger is too large, on the other hand, the released condensation heat is not sufficient to noticeably raise the temperature of the return flow into the buffer boiler and there the temperature of the zone. This would result in mixing of the storage tank, which would also reduce the gains in calorific value. Therefore, the litres must be precisely balanced with the aid of the partial flow pump. The measure for this is the change in flue gas temperature mentioned above. When this just starts to rise, the flow is correct. Fabian Lutz shortens the explanation: "It is sufficient to observe the exhaust gas sensor behind the heat exchanger. Cold cooling water already flows automatically at the start. You only have to readjust it to the volume at which the Celsius just wants to climb. Or rather, at exactly this volume, you only have to stop the readjustment, then the conditions are right.

In winter, when temperatures are below zero and the system is possibly in continuous operation, the heat exchanger would need a higher flow rate or a lower inflow temperature. Exactly this, the lower temperature, is automatically supplied by the multi-way mixer. It now sends the 30-gram return flow of the switched-on underfloor heating to the condenser. And the condenser raises the inflow from 30 °C to a valuable 50 °C. The "rendeMIX" decides on the basis of the temperatures whether the buffer storage boiler takes up this supply or whether it flows straight into the living rooms.

No legionella problem

Its almost infinite freedom in temperature control is concealed in the designation "3×4": three connections on the heating cabinet - top, middle and bottom - and four ways on the mixer, namely flow and return for the radiator and underfloor heating circuits. This architecture allows for a wide variety of mixing variants. First: The boiler switches off at 75 °C buffer water temperature and switches on when the buffer water temperature falls below the setpoint temperature or when the flow temperature falls below the setpoint temperature. The target temperature in the buffer is 55 °C, so that the fresh water heat exchanger has sufficient tapping capacity available. Olymp supplies the eco system with such a continuous flow water heater as standard. With it, the legionella problem does not exist, at least on the boiler side. Because of the cold drinking water, the temperature on the heat exchanger walls does not exceed 55 °C, even at 75 °C flow. This means that the stainless steel plates on the drinking water side remain largely free of limescale deposits.

On the surfaces that come into contact with the heating water, there is no risk anyway, because the entire system is operated with treated, fully desalinated water. However, this has nothing to do with a specification by the manufacturer Olymp. Heating engineer Lutz justifies the treatment with the installed high-efficiency pumps: "When we introduced them, we didn't realise the necessity. There were some faults. Today, with high-efficiency pumps, we automatically fill the system with fully desalinated water and also put a magnetic sludge separator in the pipes. Iron compounds simply must not be allowed to settle in the permanent magnets of the high-efficiency pumps. In the beginning, when we did not take these precautions, in individual cases the pumps failed after only a few months. We often had to remove the heads and clean them."

To the circuit diagram

The flow directions of the "3×4" type are shown in the circuit diagram (see Fig. 1). Connections 1, 7 and 2 connect the "rendeMIX" to the boiler, connections 3, 4, 6 and 5 to the heating circuits. Connection 1 sends buffer water at 70 °C in the example in the direction of the Baunach fitting with the three-way mixer at the top and the multi-way mixer ("rendeMIX") in the middle of the section of the picture with the grey background. Connection 7 loads or unloads the Olymp central unit via the "rendeMIX" and via 2 the return flows both into the cold zone of the boiler and into the condensation heat exchanger.

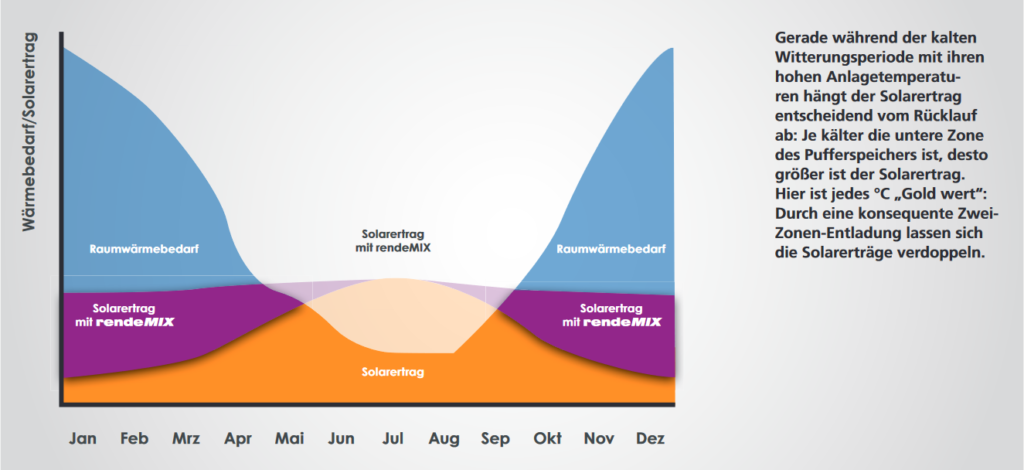

More sun in the reservoir

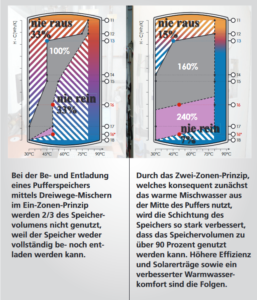

To emphasise this again: The special feature of the "rendeMIX" design in this two-mixer version is that a single actuator (plug) of three inputs always connects only two to the output, as just described on the supply underfloor heating circuit. The scheme only allows mixing either hot with cold or hot with hot water, but not hot with cold. The mixing manifold thus handles the heating water supply in the buffer very economically and thus increases its usable capacity by a verifiable 200 percent, which corresponds to a tripling of the effective buffer volume. The fact that hot buffer water from the centre or the radiator return is used instead of hot water - if hot water is sufficient - results in these two effects: Firstly, the buffer remains hot longer at the top and secondly, since this scheme returns cold water from the underfloor heating to the buffer at the bottom, the spread between hot and cold increases and thus the hot water storage volume between these two zones.

The cold water base due to the cold return from the underfloor heating circuit increases the solar yield in addition to the hot water supply and the condensation heat gains in the condensing heat exchanger in the case of an additional solar thermal system on the house roof: Not only the Olymp central unit, but also all other tanks are enabled by a 30-grd "base set" to absorb "only" 40-grd solar thermal water as well.

For more information, see: