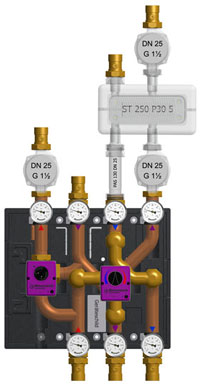

rSYS 3×4+3mix

2-circuit compact solution for system separation at the buffer

Those of you who have ever had the pleasure of a rendeMIX 3×4+3mix on a buffer storage tank know what we are talking about: from doubling to tripling the usable buffer volume. The fact that such results can really be achieved with the methods used here - return utilisation and two-zone discharge - has already been reported several times in the trade press, for example in Sanitär+Heizungstechnik 3/2017:

Those of you who have ever had the pleasure of a rendeMIX 3×4+3mix on a buffer storage tank know what we are talking about: from doubling to tripling the usable buffer volume. The fact that such results can really be achieved with the methods used here - return utilisation and two-zone discharge - has already been reported several times in the trade press, for example in Sanitär+Heizungstechnik 3/2017:

In order to make this possible also on systems with system separation, we are now pleased to offer you the rSYS 3×4+3mix present. This has been precisely matched to the operation of a system separation in the low-temperature circuit by means of flow control. This means that nothing stands in the way of efficient storage utilisation!

Application example: Buffer with peak-load boiler

Application example buffer with peak load boiler

End customer brochure Storage - The two-zone principle

What are the general advantages of the two-zone principle?

- Up to 100% more yield with solar systems

- Up to 200% more capacity in the buffer tank

- Reduction of the amortisation period of the entire heating system

- Save fuel - every year

- Hot water faster and longer

What makes the rSYS 3×4+3mix so special?

On the basis of the rMIX 3×4+3mixwhich can save enormous energy costs through efficient use of the buffer volume, we have developed the rSYS 3×4+3mix developed for operation with a system separation in the low-temperature circuit (usually underfloor heating). Unlike conventional systems, in which the system separation is constantly loaded with the same flow rate and the heating pump runs continuously (even when there is only a low heat demand), the rSYS 3×4+3mix react to any change in the heat demand. If there is no demand, there is no active consumption! By actively adjusting the water quantity in partial load operation, the return temperature remains low.

The big advantage lies in the flow control

The mixer of the low-temperature circuit is controlled via the heating control. If the heat demand of the low-temperature circuit drops, the mixer is closed further. A high-efficiency pump upstream of the system separation reacts to the closing of the mixer and reduces the delivery pressure further. The end result?

- The required amount of heat is supplied with the smallest possible amount of water, resulting in the lowest return temperature.

- The high-efficiency pump, before the system separation, adapts to the heat demand of the low-temperature circuit and thus consumes less electricity, due to the closing of the mixer.

Please also have a look at: The jet principle - Regenerative solution for