Why Jörg de Jong would recommend rendeMIX to every skilled craftsman

Baunach specialist partner, Mr Jörg de Jong, Managing Director of SEDEJO GmbH in Frechen, has implemented the rendeMIX heat distribution system with a condensing boiler cascade. We were able to ask Mr. de Jong about the system and find out why he uses rendeMIX every time:

Baunach specialist partner, Mr Jörg de Jong, Managing Director of SEDEJO GmbH in Frechen, has implemented the rendeMIX heat distribution system with a condensing boiler cascade. We were able to ask Mr. de Jong about the system and find out why he uses rendeMIX every time:

Have you already had experience with the efficiency of the plant?

Yes, I have. Before, there were three separate systems. Now we only have the consumption of one system. So in principle, two systems have been eliminated and therefore their gas consumption as well.

Will Baunach be used again in the future?

On the systems with more than one mixing circuit in any case. We haven't done hot water and mixer circuit together yet, but that would also be worth a try. I see potential there, too.

Would you recommend craftsmen to use Baunach?

Absolutely. In my opinion, there is nothing that speaks against it, because it is much faster and easier to assemble is.

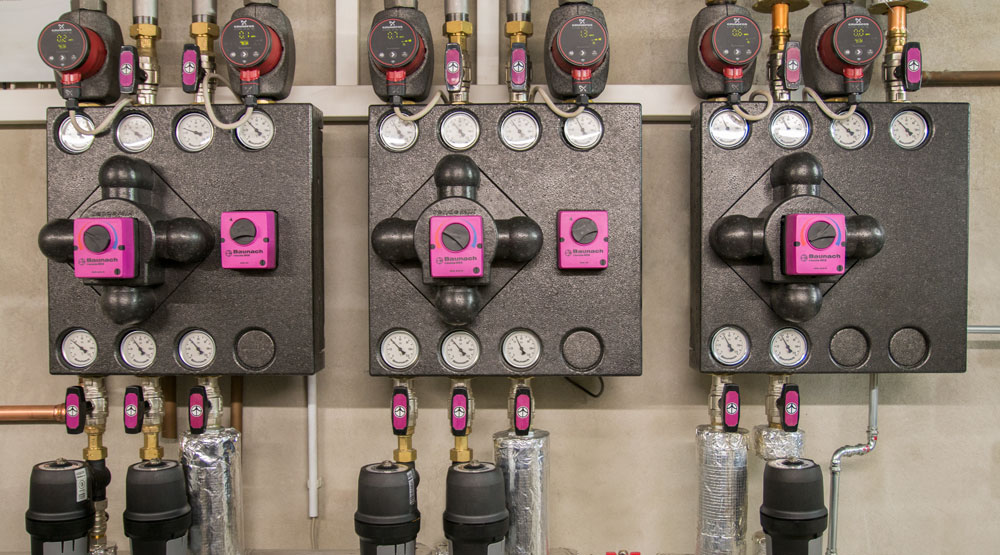

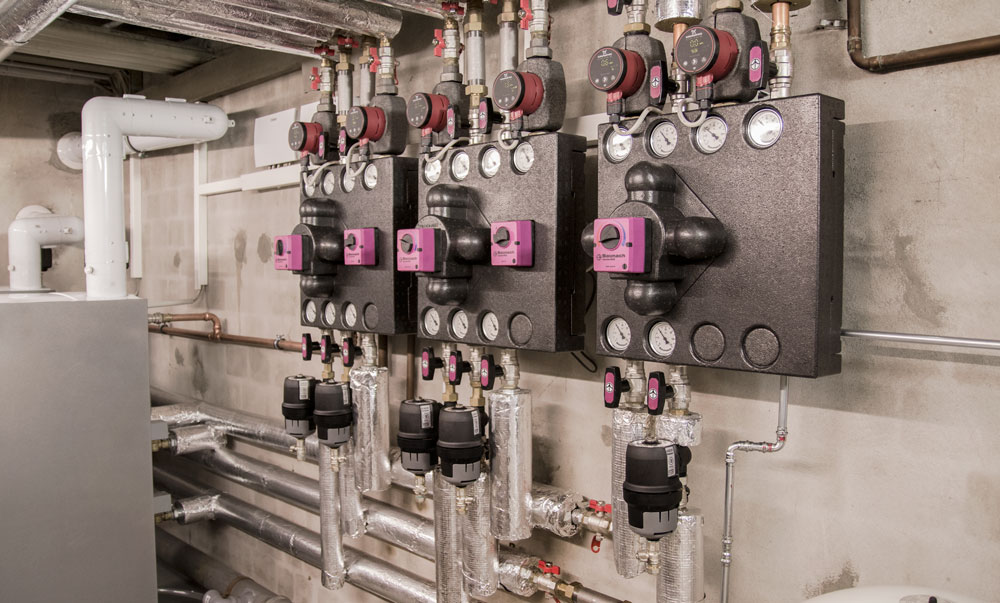

I don't need any manifold bars or two groups that I have to put on the manifold bar with screw fittings and everything. The pumps stand freely above it and the mixer is also cleanly insulated. So I don't have any big holes in the mixer insulation, as is usually the case with pump groups. The mixer is really completely closed and only the servomotor sticks out at the front.

Even if I gave up all the rest of the benefits, it would still be easier to assemble than standard assemblies.

"I get the high efficiency that the system offers for free. That's why we use rendeMIX every time."

How do rendeMIX mixers make the heating system highly efficient in contrast to the original standard distribution?

1. integrated return use

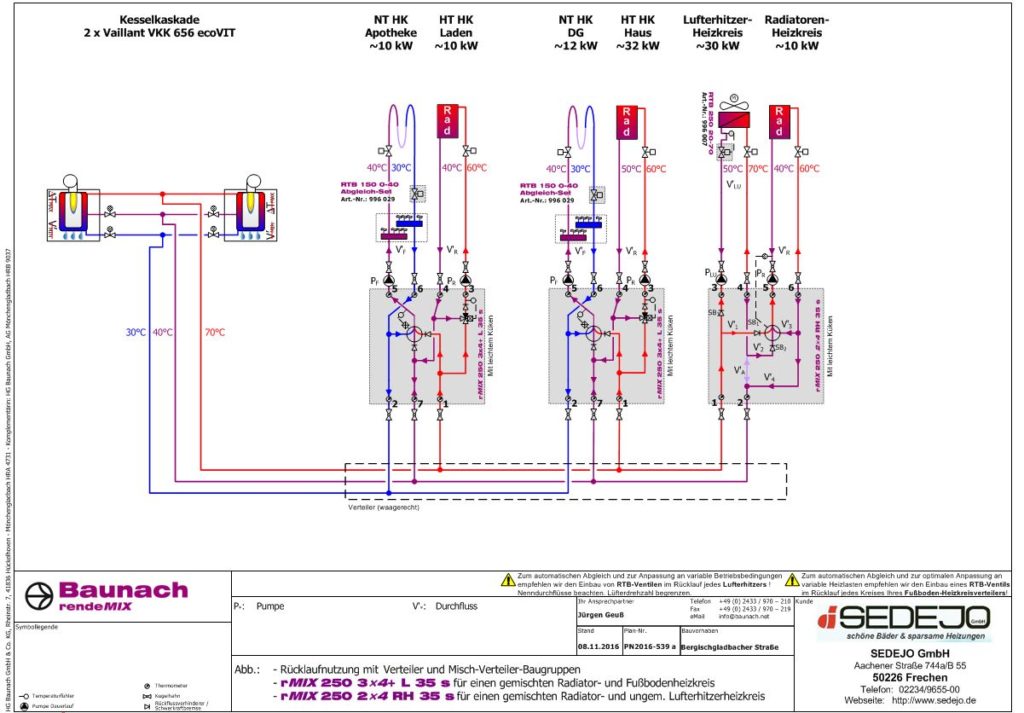

The rMIX 250 2×4 RH 35 s connects 2 circuits (high-temperature / low-temperature circuit) with each other and ensures that the high-temperature circuit return is admixed to supply the low-temperature circuit. In this way, the return flow of the higher temperature circuit is processed in the best possible way and the heat generator receives colder return water. At the same time, the system is hydraulically decoupled so that each circuit can operate independently without any problems.

Example: The rMIX 250 2×4 RH 35 s uses the return (purple) of the air heater heating circuit (high temperature heating circuit) to supply the radiator heating circuit (low temperature circuit).

2. double return use + two-zone principle via 3 connections on the mixer

The two rMIX 250 3×4+ L 35 s have another middle connection via which the return water of the respective upstream mixer from the middle distribution chamber (purple) can be used further in order to use as little boiler water as possible and to make maximum use of the thermal energy in circulation. In addition, the colder return water from the underfloor heating systems is routed to the lowest distribution chamber (blue), while the warmer excess return water from the radiators can be routed to the middle distribution chamber. This creates maximum calorific value effect at the second return of the boiler cascade through the two-zone principle (also ensures improved stratification at buffer storage tanks).

Example: The common return of the two heating circuits "air heater" and "radiators" connected in series from the rMIX 250 2×4 RH 35 s flows via the middle chamber (purple) to the next mixer rMIX 250 3×4+3mix L 35 s for the heating circuits "DG" and "House". This can now additionally be used for the low-temperature heating circuit "DG" if not enough return water comes back from the "House" circuit. If the return water of the "rMIX 2×4" is not needed at this point, the next mixer in the row can use the return water for the low-temperature circuit "Pharmacy".

Conclusion

The original heating system not only consumed three times the expensive fuel and produced three times the carbon dioxide; the Baunach rendeMIX multi-way mixing manifolds are also much faster and easier to install than conventional standard assemblies.