Return flow utilisation

Advantages at a glance

- on average 20% savings in heating costs

- Maximum possible calorific value benefit

- Hydraulic separator, distributor and at least 1 pump saved

- Longer service life of the condensing boiler

The heat from your condensing boiler does not go directly into your radiators or underfloor heating; it first flows through a distributor and a mixer. It's very similar to the power of your car engine, which must first be put on the road through the gearbox and tyres before you get any benefit from it.

What does rendeMIX bring us?

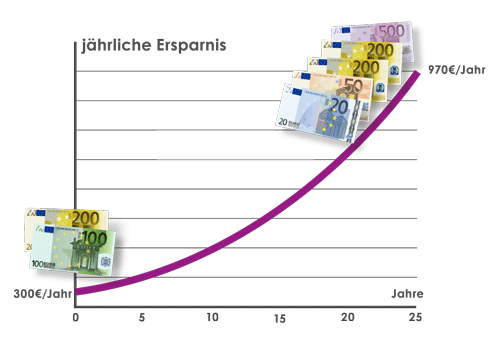

The annual savings increase with the energy price

The prices for oil and gas have been fluctuating strongly for years. But over the lifetime of a heating system, they rise: On average by at least 5% per year.

8,423km less CO2 - every year

With the CO2 emissions saved by rendeMIX of around 800kg/year, your family could circle the earth once in five years - without having to give up even one degree Celsius in heating comfort! (EU 2020 CO2 target: 95g/km)

How does the return flow usage work?

Because rendeMIX makes the return of the radiators the flow of the underfloor heating, the water flows back to the condensing boiler much colder. Colder return water creates more condensate and more heat from the flue gas gets into the heating water, so that through rendeMIX return use less gas or oil is required. Of course, the rendeMIX can also be combined with other heating applications that operate with different system temperatures (e.g. air heater/radiator, radiant ceiling panels/radiator, hot water tank/area heating ...etc.). The return flow of the first heating circuit does not necessarily have to be hotter than the flow of the mixing circuit for the return flow to work. In the magnifying glass you can see how hot return water from radiators is used for the flow for the floor circuits. If required rendeMIX mixes hot or cold water to achieve the desired temperature. Operating the radiators or the floor circuit alone is also part of the functional scope of the rendeMIX .

In the video you can see our rMix 2×4 which is used as a mixing manifold (with integrated return utilisation) for combining an unmixed heating circuit (H) with a mixed heating circuit (M) (also available as a rMix 2×4+ for two mixed heating circuits). The mixer primarily uses return water from the first unmixed heating circuit (H) as flow water for the second mixed heating circuit (M). This results in efficient return flow utilisation. If the temperature is too low, a certain amount of hot water from the boiler flow is added. If it is too high, cold water from the return of the mixed circuit is added. If the flow rates of the two circuits are unequal, pressure equalisation can take place via the integrated bypass, as with a hydraulic separator, so that the system is hydraulically decoupled. The smaller the temperature spread between the heating circuit return and the mixing circuit flow, the less the mixer has to add to achieve the corresponding temperature. In this way, the entire heat quantity in circulation is utilised before it is fed to the boiler as a return flow, and the return flow temperature to the condensing boiler is considerably reduced. This results in maximum calorific value benefit.

In the video you can see our rMix 2×4 which is used as a mixing manifold (with integrated return utilisation) for combining an unmixed heating circuit (H) with a mixed heating circuit (M) (also available as a rMix 2×4+ for two mixed heating circuits). The mixer primarily uses return water from the first unmixed heating circuit (H) as flow water for the second mixed heating circuit (M). This results in efficient return flow utilisation. If the temperature is too low, a certain amount of hot water from the boiler flow is added. If it is too high, cold water from the return of the mixed circuit is added. If the flow rates of the two circuits are unequal, pressure equalisation can take place via the integrated bypass, as with a hydraulic separator, so that the system is hydraulically decoupled. The smaller the temperature spread between the heating circuit return and the mixing circuit flow, the less the mixer has to add to achieve the corresponding temperature. In this way, the entire heat quantity in circulation is utilised before it is fed to the boiler as a return flow, and the return flow temperature to the condensing boiler is considerably reduced. This results in maximum calorific value benefit.

Are there any other advantages?

Lower investment costs and fewer boiler starts

But that's not all: rendeMIX eliminates the hydraulic separator including sensor and controller module as well as the radiator pump. In systems with system separation in the mixing circuit, you save another pump upstream of the system separation when using the rMIX 2×4 jet. This saves you money from the very first moment. In addition, there is less power consumption and fewer boiler starts. No one offers more advantages!

Longer service life and less maintenance required on the condensing boiler

A rendeMIX heat distribution system ensures a high level of benefit from your condensing boiler thanks to cold returns. This leads not only to low heating costs, but also to low maintenance and a long service life. This is because the cold returns in the boiler produce more condensation water, which constantly flushes the heat exchanger. This prevents stubborn deposits and their consequences from occurring in the first place.