Filter blog posts by...

All blog posts Planning: How does it work? Specialist partners report: References News and datesEfficiency finally simple

+ Baunach system efficiency in heat distribution and heat storage

+ Easier and faster assembly

+ Less space required

+ High-quality insulation of all connections

+ Best layering and layer retention

+ Versatile in use

+ Specially developed for heat pumps, wood-burning stoves and solar thermal energy

+ Stay informed about the earliest possible delivery date

If the result is to be right, ...

Jakob Appelhans, Hans-Georg Baunach and Till-Marlo Lüking (from left to right) at the presentation of the DEUTSCHE TGA-AWARD 2024 by the trade magazine "Moderne Gebäudetechnik" of HUSS-MEDIEN GmbH at GET Nord in Hamburg on 22 November 2024

then specialist tradesman Jakob Appelhans from Sorpetaler Energie in Sundern (Sauerland) trusts the team from Baunach rendeMIX. Because maximum efficiency through low return temperatures and perfect buffer stratification have been our speciality for over twenty years. (more…)

Heat pump and buffer stratification? That's not only possible on St Nicholas' Day!

Till-Marlo Lüking (l.), Baunach company, and Hans Stefan Albers (r.), bbz Arnsberg, at work

Dear friends of the Arnsberg practical seminar,

on 6 December 2024, we have worked together with the bbz Arnsberg the next Practical seminar 2025 prepared. For the first time, we have used our tried and tested rSTOR Buffer storage tank via a newly supplied

DUVbox 2×3 by a heat pump and the whole thing recorded thermographically.

Now also on social media!

We can now also be reached on popular social media platforms such as Facebook, Instagram, Twitter and WhatsApp. There you can take a look behind the scenes of Baunach and its product manufacturing.

We can now also be reached on popular social media platforms such as Facebook, Instagram, Twitter and WhatsApp. There you can take a look behind the scenes of Baunach and its product manufacturing.

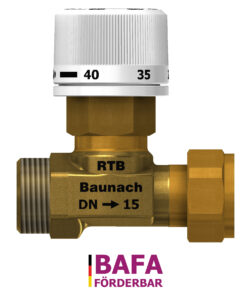

New return temperature limiter "RTB T0-50 balancing valve (slow)" with integrated temperature sensor

Recently we have started to offer for our innovative Baunach products new return temperature limiter with a temperature range of 0-50 °C and integrated temperature sensor on. For you, this means that you no longer have to invest time in installing a temperature sensor. You also save money, as no additional components such as T-pieces or immersion sensors are required.

Recently we have started to offer for our innovative Baunach products new return temperature limiter with a temperature range of 0-50 °C and integrated temperature sensor on. For you, this means that you no longer have to invest time in installing a temperature sensor. You also save money, as no additional components such as T-pieces or immersion sensors are required.

The RTB valve is ideally suited for single-pipe heating systems, ceiling radiators, swimming pool heat exchangers or a radiator and underfloor heating system. Due to the inertia, the valve is not Suitable for air heaters and ventilation and air-conditioning systems.

Benefit from our innovative & efficient solutions today!

rendeMIX Update - new ball valves for all light versions DN25

In the past, many customers have asked us about our ball valves in the DN25 version. These are indeed functional - but would not fit our high-quality assembly. In addition, there would be a high risk of using a slotted screwdriver instead of an internal hexagon. This could damage the component.

In the past, many customers have asked us about our ball valves in the DN25 version. These are indeed functional - but would not fit our high-quality assembly. In addition, there would be a high risk of using a slotted screwdriver instead of an internal hexagon. This could damage the component.

As part of the continuous improvement of our products, we have replaced the previous ball valve with a higher quality one with an aluminium butterfly handle.

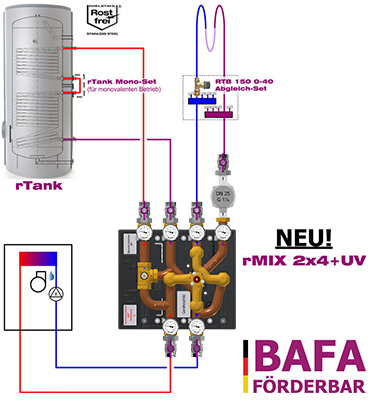

New - Return flow utilisation on hot water tanks!

Have you ever asked yourself why you can't use the hot return of hot water tanks to supply a heating circuit with it? The whole thing would save you a lot of energy if there were a way.

We would now like to present this possibility to you!

Welcome to the FÖRDERBAR

Almost all Baunach products are now eligible for BAFA funding of 15% (plus 5% iSFP bonus).

Promotion for all:

Look out for this symbol on our products:

20% BAFA subsidy on hydraulic balancing in no time at all

As of now, our return temperature limiter valve for underfloor heating circuits is eligible for funding from BAFA as part of hydraulic balancing.

As of now, our return temperature limiter valve for underfloor heating circuits is eligible for funding from BAFA as part of hydraulic balancing.

The RTB valve is a thermostatic return temperature limiter with adjustable maximum temperature and fixed minimum flow in the order of 0.5% of the nominal flow. (more…)

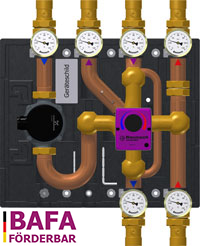

20% BAFA subsidy for rendeMIX with high-efficiency pump

As of now, our classic 2-circuit return utilisation assemblies with built-in pump are on BAFA's list of eligible pumps.

As of now, our classic 2-circuit return utilisation assemblies with built-in pump are on BAFA's list of eligible pumps.

"The subsidy amounts to 30 % of the net investment costs for services related to both the replacement of heating circulation pumps and hot water circulation pumps with high-efficiency pumps and related to hydraulic balancing, up to a maximum of 25,000 euros per location." (Source: bafa.de)

Through this funding programme, our "a" Assemblies with integrated high-efficiency pump even cheaper than Without pump. This way, your customers end up saving even more on their investment and also receive a new pump. (more…)

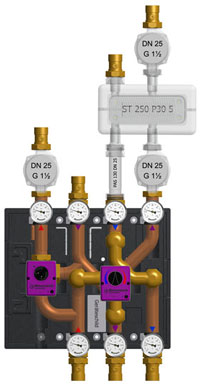

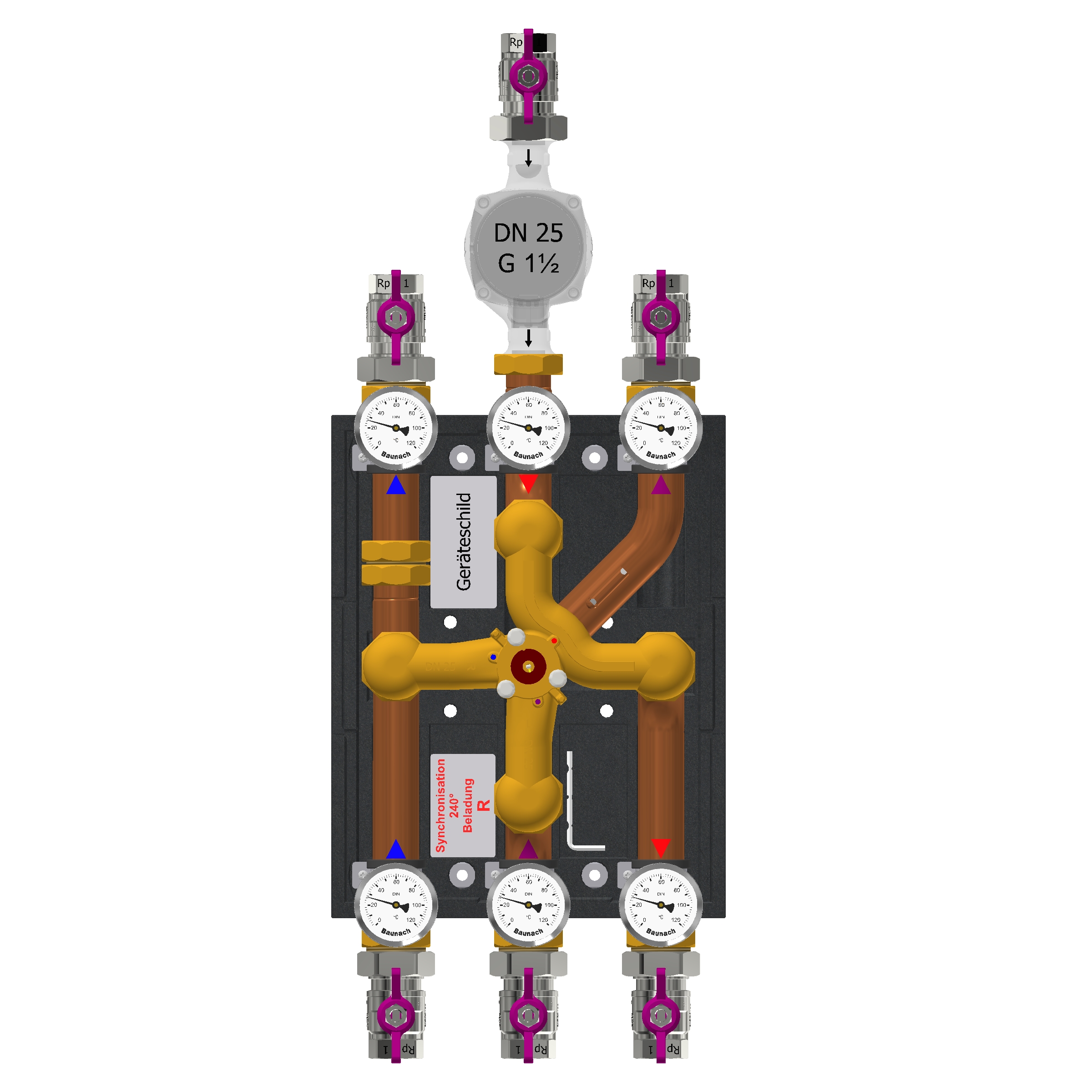

rSYS 3×4+3mix

2-circuit compact solution for system separation at the buffer

Those of you who have ever had the pleasure of a rendeMIX 3×4+3mix on a buffer storage tank know what we are talking about: from doubling to tripling the usable buffer volume. The fact that such results can really be achieved with the methods used here - return utilisation and two-zone discharge - has already been reported several times in the trade press, for example in Sanitär+Heizungstechnik 3/2017:

Those of you who have ever had the pleasure of a rendeMIX 3×4+3mix on a buffer storage tank know what we are talking about: from doubling to tripling the usable buffer volume. The fact that such results can really be achieved with the methods used here - return utilisation and two-zone discharge - has already been reported several times in the trade press, for example in Sanitär+Heizungstechnik 3/2017:

In order to make this possible also on systems with system separation, we are now pleased to offer you the rSYS 3×4+3mix present. This has been precisely matched to the operation of a system separation in the low-temperature circuit by means of flow control. This means that nothing stands in the way of efficient storage utilisation!

Application example: Buffer with peak-load boiler

Application example buffer with peak load boiler

A good feeling is half the battle

What is the quality of a control loop?

Sensor on CHP

A controller constantly compares a specified SET value with a measured ACTUAL value and determines a reaction (manipulated variable) from the difference (deviation) with the aim of making the deviation between the SET and ACTUAL values as small as possible. If, for example, a constant return temperature of 60°C is required for a CHP unit, this is the SET value, while the ACTUAL value is determined by a temperature sensor. A possible reaction would be a three-point signal that opens, stops or closes a mixing valve via an electric drive so that the return temperature is raised, maintained or lowered.

Why do you actually need both?

Two-zone loading and two-zone unloading?

Which by now word has got around ...

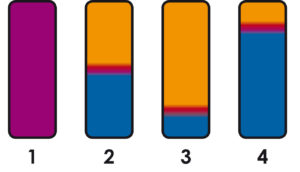

States of charge in the buffer storage tank

is that the best possible stratification is the be-all and end-all of the efficient use of buffer storage tanks. Because only the best possible stratified storage tank can still absorb heat when it is already relatively full and release heat when it is already relatively empty. The secret of this benefit lies in the fact that with good stratification the storage tank is always hot at the top and always cold at the bottom (Fig., buffers 2-4), while the thoroughly mixed storage tank is warm from top to bottom (Fig., buffer 1). The border between hot and cold should be as abrupt as possible. The fuller the storage tank, the lower (picture, buffer 3), the emptier it is, the higher (picture, buffer 4) this limit is. In any case, a well stratified storage tank should not contain any hot water at all. (more…)

Parallel or one behind the other?

What to do with several buffer storage tanks?

Systems are increasingly being equipped with buffer storage tanks, whether for heat pumps, wood boilers, CHP units or solar thermal systems. It is not uncommon for the required storage volume to have to be divided between several smaller tanks because only these will fit through the doors or stairwells. This raises the question of whether a parallel or series connection of buffer cylinders is the better solution. As is usually the case in life, the appropriate answer is: "It depends."

Systems are increasingly being equipped with buffer storage tanks, whether for heat pumps, wood boilers, CHP units or solar thermal systems. It is not uncommon for the required storage volume to have to be divided between several smaller tanks because only these will fit through the doors or stairwells. This raises the question of whether a parallel or series connection of buffer cylinders is the better solution. As is usually the case in life, the appropriate answer is: "It depends."

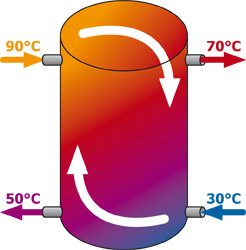

Buffer connection on one side

A simple way to improve stratification in the buffer

Two-sided buffer connection

It is very common to see in hydraulic plans and installations that heat generators and heat consumers are connected to buffer tanks in separate connections for each height (top, bottom, possibly also centrally). However, this often has a negative effect on the flow and thus on the stratification of the buffer tank, as the following example illustrates. Let's assume that a 28kW log boiler (90°C flow temperature) loads a buffer storage tank, while at the same time a radiator circuit (70/50°C) and a floor circuit (40/30°C) are supplied with a total of 14kW. Let us further assume that the two heating circuits are connected to the buffer by rendeMIX return utilisation with 70/30°C in total. When the buffer is connected on both sides, the entire boiler volume flow flows into the buffer at the top left and is removed again at the bottom left. In addition, the entire system volume flow is taken out at the top right and fed back in at the bottom right. The following formula therefore applies: (more…)

Pump speed and flow temperature

More efficiency at the buffer tank with less effort

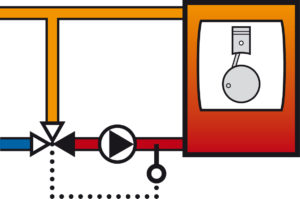

Some regenerative heat generators, such as wood or pellet boilers or CHP units, may only be operated with a fixed return temperature. For this purpose, a return flow increase (RLA) is used, which feeds parts of the heat generator flow into its return flow. Very often, the pump speed is selected unnecessarily high, which reduces the efficiency of the buffer storage loading. (more…)

Some regenerative heat generators, such as wood or pellet boilers or CHP units, may only be operated with a fixed return temperature. For this purpose, a return flow increase (RLA) is used, which feeds parts of the heat generator flow into its return flow. Very often, the pump speed is selected unnecessarily high, which reduces the efficiency of the buffer storage loading. (more…)

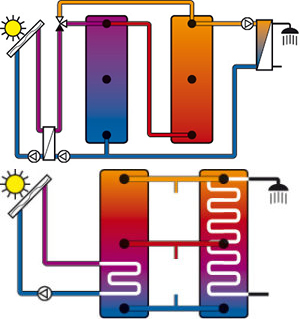

Drinking water reservoir? If already - then already!

The new rTANK

Until a few years ago, drinking water storage tanks were considered the solution par excellence for heating drinking water, and they are still widely used in the private sector today. And who is surprised? After all, they offer a comparatively high level of comfort with little technical effort and are available at a reasonable price.

With the advent of solar systems, however, it became necessary to reduce the return temperatures to the heating system as low as possible. And at about the same time, the legionella issue arose. Both spoke in favour of instantaneous water heater systems, the hygiene storage tank with corrugated tube heat exchanger and the fresh water station. But is this additional expense really always justified and aren't there other disadvantages? (more…)

Thermostatic balancing with RTB valves

The purpose of hydraulic balancing

is to provide the right amount of water to each consumer in a distribution network. This must not be too small, because otherwise the consumer will not be sufficiently supplied with heat. But it must also not be too large, because otherwise its return temperature will rise too much, the supply to other consumers will be impaired and the network efficiency will drop. But what is the "right" amount of water? (more…)

is to provide the right amount of water to each consumer in a distribution network. This must not be too small, because otherwise the consumer will not be sufficiently supplied with heat. But it must also not be too large, because otherwise its return temperature will rise too much, the supply to other consumers will be impaired and the network efficiency will drop. But what is the "right" amount of water? (more…)

Exhaust gas condenser, return flow boost and buffer efficiency

Flue gas condensers continue the eco-trend towards condensing boiler technology

The idea of extracting additional heat from the combustion exhaust gas by condensing the water vapour it contains has now become widely accepted under the term condensing technology for natural gas and fuel oil boilers. In this respect, it can be assumed that the trend towards condensing technology will also continue for wood boilers and CHP units, especially since there are further advantages to be recorded for each of these technologies: (more…)

The idea of extracting additional heat from the combustion exhaust gas by condensing the water vapour it contains has now become widely accepted under the term condensing technology for natural gas and fuel oil boilers. In this respect, it can be assumed that the trend towards condensing technology will also continue for wood boilers and CHP units, especially since there are further advantages to be recorded for each of these technologies: (more…)