Product search

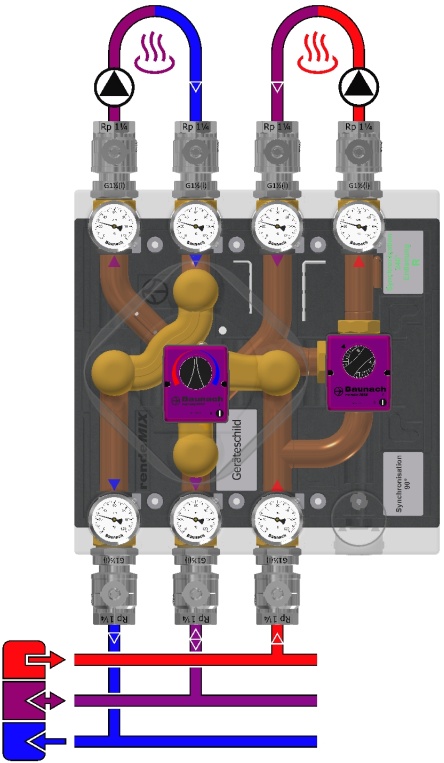

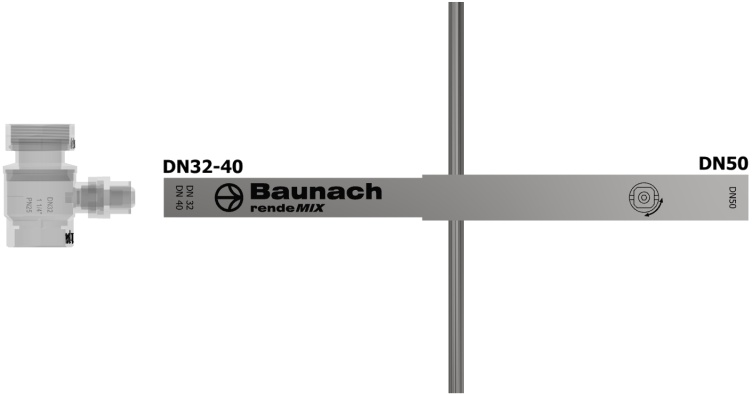

rMIX DN32 3x4+3mix L

Recommended accessories

|

Schl KuH DN32-50 set996167 |

|

|

ISO KuH DN32 G1½(i)xRp1¼996086 |

Configure product variant

Performance class

Kvs = 13.6 • V'max[100mbar] = 4.3m³/h

Q'max[20K] = 100kW

2nd mixing circuit (LT):

Kvs = 18.9 • V'max[100mbar] = 6m³/h

Q'max[10K] = 70kW

Flow direction producer

Pump flange

Product documentation

Assembly instructions

Assembly instructions: For specialist partners only.

Please log in here or register here

Actuator multi-way mixer: For specialist partners only.

Please log in here or register here

Actuator three-way mixer: For specialist partners only.

Please log in here or register here

Data sheet

GAEB

Tender text

Baunach article master data Version: 19.11.24

BAFA funding opportunity as part of heating system optimisation through hydraulic balancing and installation of separate control technology

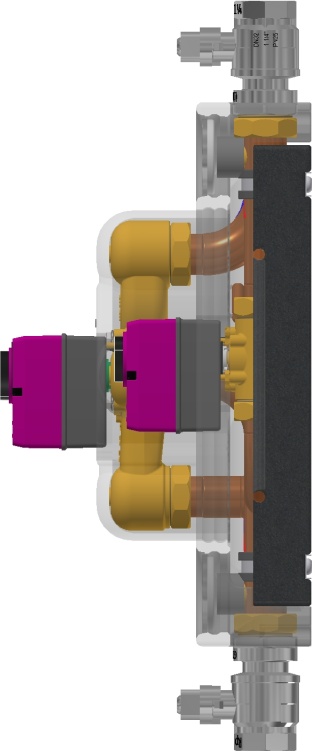

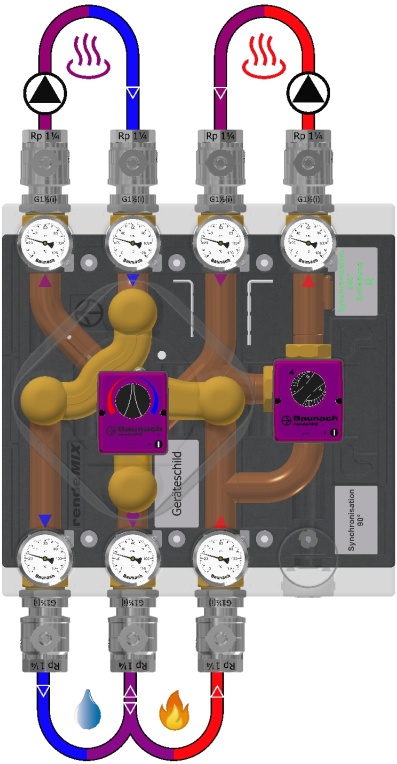

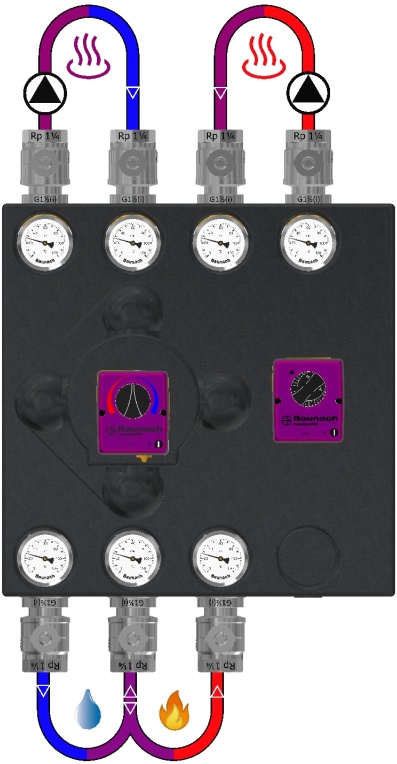

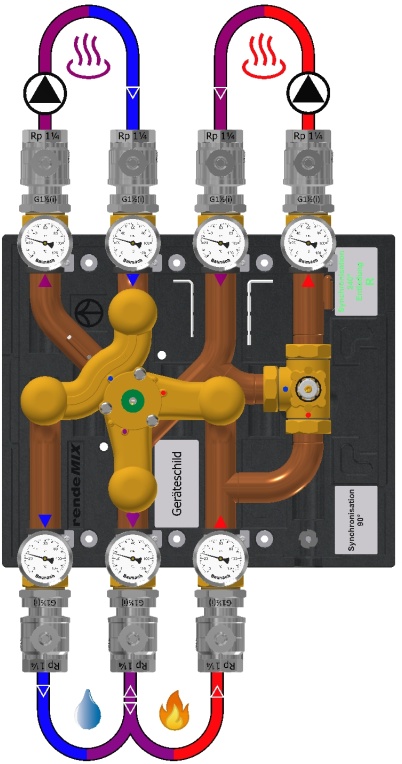

rendeMIX multi-port mixing manifold with 3/3-way tangential mixing valve DN32×G1½(a) MsGuss (green adapter) and 3-way mixing valve DN32×G1½(a) Ms58, plug and cover Ms58

For highly efficient two-zone unloading of a buffer tank in a mixed low-temperature circuit (2nd mixing circuit) with highly efficient use of the return flow of a mixed high-temperature circuit (1st mixing circuit).

1st mixing circuit: EMS 90-3P actuator, 230V~ 50Hz 3.5VA 3-point signal, 5Nm (240h), 90°, 70s, grey adapter. 2nd mixing circuit: EMS 240 actuator, 230V~ 50Hz 3.5VA 3-point signal, 5Nm (240h), 240°, 93s

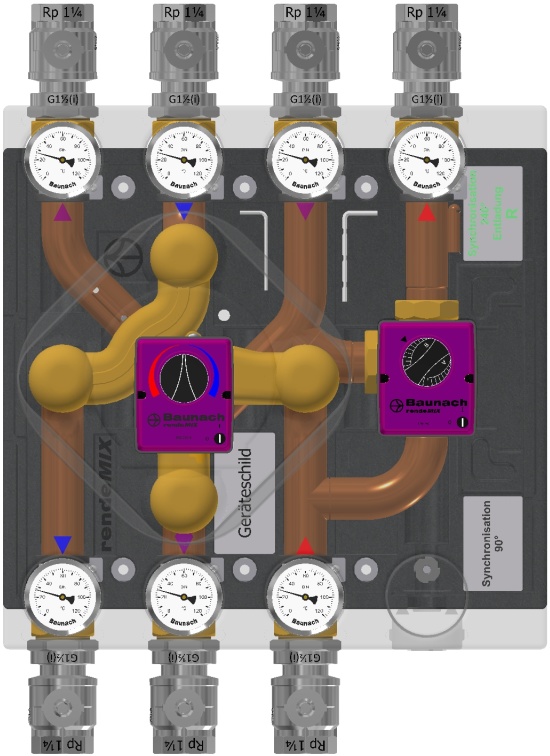

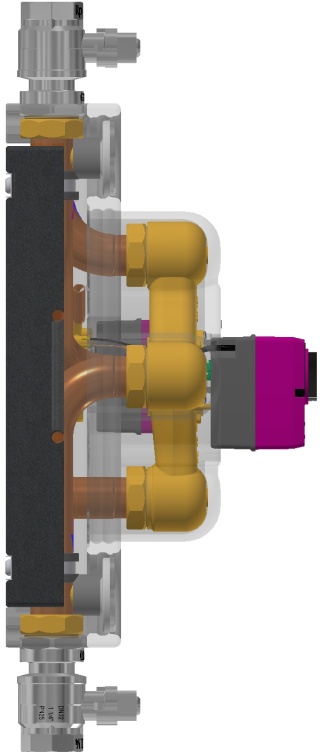

Two-circuit manifold assembly with 3 connections to the heat generator (buffer or boiler with flue gas heat exchanger), CuØ35×1, pipe spacing 100mm, DN32×G1½(a) flat

3 integrated gravity brakes/backflow preventer, Dp10mbar

1. mixing circuit (HT): Kvs = 13.6 - V'max[100mbar] = 4.3m³/h - Q'max[20K] = 100kW - leakage rate < 0.1% - 2nd mixing circuit (NT): Kvs = 18.9 • V'max[100mbar] = 6m³/h • Q'max[10K] = 70kW • Leakage rate < 0,1%

7 Thermometer 0-120°C, Ø63mm, soldering sleeves Ms58

7 Ball valve screw connections, DN32 passage, PN25, G1½(i)×Rp1¼ flat-sealing, stuffing box, spindle with square drive SW25

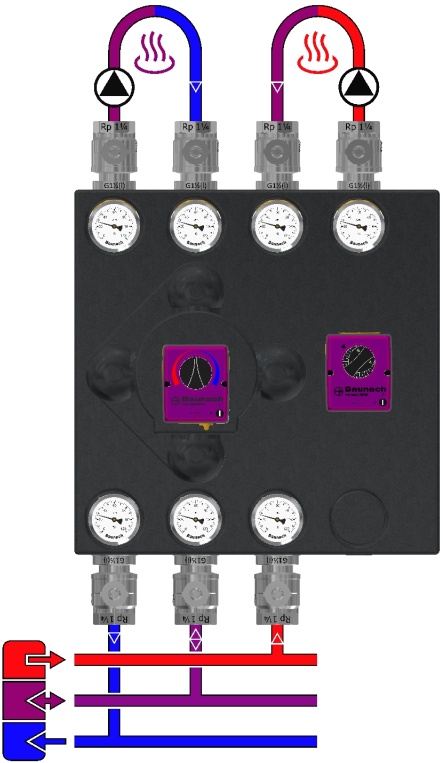

Insulating moulded tray EPP 40g/l, black, 450×450mm, quick assembly kit

Without pump flanges

Assembly does NOT include pump compensator - PAS L180 (Part No.: 001 338)

Assembly does not contain a pump

Model DN 32, PN 10bar, Tmax 120°C

Performance data

1. mixing circuit (HT): Kvs = 13.6 - V'max[100mbar] = 4.3m³/h - Q'max[20K] = 100kW - leakage rate < 0.1% - 2nd mixing circuit (NT): Kvs = 18.9 • V'max[100mbar] = 6m³/h • Q'max[10K] = 70kW • Leakage rate < 0,1%